Bucket Elevator for Rapeseed

For transporting oil crops such as rapideed from low places to designed heights

| Elevation height | 2-60m |

| Conveyment capacity | 3-100 tons/h |

| Power | 3-30KW |

| Hopper volume | 1.8-12.5L |

| Material | Carbon steel/stainless steel |

What is Bucket Elevator for Rapeseed?

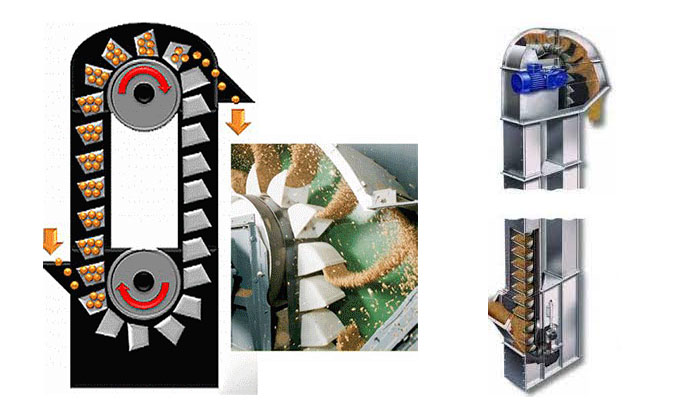

Bucket Elevator for Rapeseed is a continuous conveying equipment for vertically transporting oil crops such as rapeseed. It consists of a series of hoppers fixed on chains or belts. These hoppers dig materials from the bottom as the transmission runs, lift them to the top, and then unload them through centrifugal force or gravity to complete the vertical conveying process of the material.

Compared with ordinary conveying equipment, Bucket Elevator for Rapeseed has the characteristics of compact structure, high conveying efficiency and small footprint. A standard TD bucket elevator can handle 5-100 tons of rapeseed per hour, and the lifting height can reach 30-60 meters, meeting the production needs of large and medium-sized grain and oil processing plants.

Why choose Bucket Elevator for Rapeseed?

Rapeseed bucket elevators have the characteristics of high conveying efficiency, low crushing, sealing and dust-free in grain and oil processing, and can transport rapeseed well:

High vertical conveying efficiency: Direct vertical improvement, no slope or turn required, saving more than 50% of space

Closed dust-free design: fully enclosed structure effectively controls dust, making the working environment cleaner and safer

Low crushing rate: Optimized designed hopper and speed to ensure rapeseed integrity >99%

Energy consumption economy: energy consumption is reduced by 30-40% compared to pneumatic conveying systems

How does Bucket Elevator for Rapeseed work?

When Bucket Elevator for Rapeseed is started, the rapeseed at the bottom feed port is scooped up by a running hopper and moves upwards with the pulling member (chain or belt). When reaching the top drive wheel, the hopper generates centrifugal force due to the change in movement direction, throwing the material into the discharge port to complete the lifting process.

Bucket Elevator for Rapeseed Parameters

| Model | Max Feed Size (mm) | Capacity (Ton/Hour) | Lifting Speed (m/s) | Belt Width (mm) | Lifting Height (m) |

| TD160 | 25 | 5.4-16 | 1.4 | 200 | <40 |

| TD250 | 35 | 12-35 | 1.6 | 300 | <40 |

| TD315 | 45 | 17-40 | 1.6 | 400 | <40 |

| TD400 | 55 | 24-66 | 1.8 | 500 | <40 |

| TD500 | 60 | 38-92 | 1.8 | 600 | <40 |

| TD630 | 70 | 85-142 | 2 | 700 | <40 |

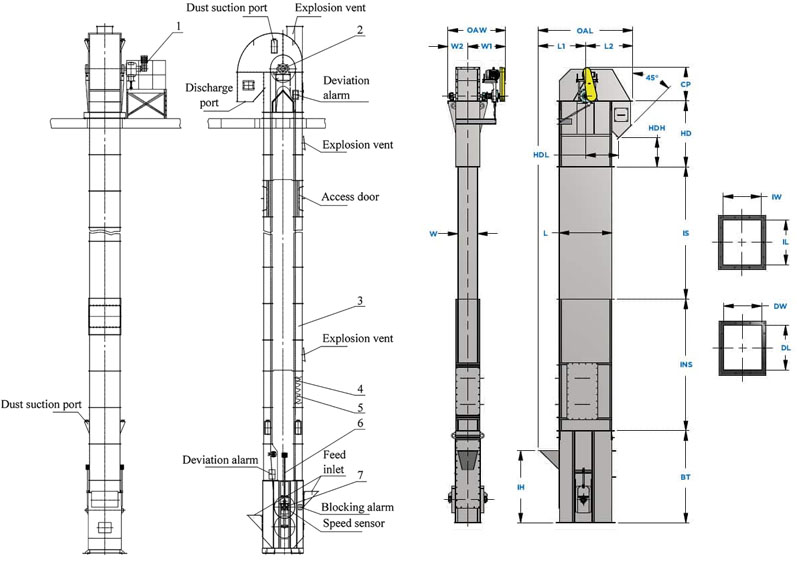

What are the structural components of Bucket Elevator for Rapeseed?

Bucket Elevator for Rapeseed mainly consists of a drive device (motor, reducer), head cover (unloading port), traction components (belt or chain), hopper (steel or plastic bucket), barrel (closed housing), tensioning device (bottom adjustment mechanism), feed port (bottom feeding section) and observation window (understanding port). Its structural design focuses on sealing to prevent dust spillage, and the hopper shape is optimized to adapt to the fluidity of rapeseed, ensuring efficient improvement and reducing crushing rate. It is suitable for continuous transportation needs of the grain and oil processing industry.

What are the applications of Bucket Elevator for Rapeseed?

Bucket Elevator for Rapeseed is used in the grain and oil processing, agricultural warehousing and feed production industries, and is mainly used to vertically transport rapeseed and its processing by-products. Typical application scenarios include: raw material silo and pretreatment section of the oil press; material in and out of the vertical silo in the grain and oil storage center; material transfer of the biodiesel production line. It can improve complete rapeseed, broken grains, pressed rapeseed meal, and processed intermediates that have been dried/dehulled. Its closed structure is particularly suitable for oil crops that are easily scattered, which can achieve efficient transportation while maintaining material integrity and meet the continuous production needs of oil and grease processing enterprises.