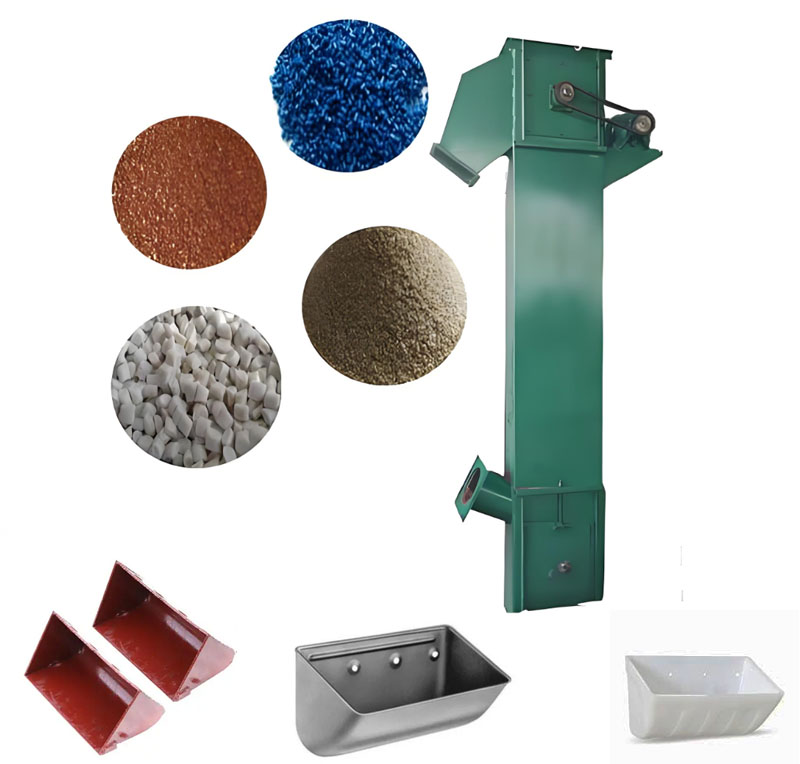

Bucket Elevator for Plastic Pellets

Used for vertical lifting of various plastic particles such as PP, PE, PS, ABS, etc. from low to high in the plastic processing industry

| Lifting height | 3-80 meters, can be customized according to specific needs. |

| Conveying capacity | 5-300 tons/hour |

| Hopper type | Stainless steel, carbon steel and food grade ABS hopper |

| Drive power | 0.75-75kW (adjusted according to height and conveying volume) |

What is Bucket Elevator for Plastic Pellets?

Bucket Elevator for Plastic Pellets is an elevator specially used for vertical transportation of plastic pellets (such as PP, PE, PS, ABS, PVC, etc.). It uses chains or belts to pull the bucket to achieve efficient and closed material lifting to avoid dust pollution. It can quickly and stably transport plastic pellets from low to high positions. The maximum lifting height is 80 meters, and the lifting capacity can reach 2 to 300 tons/hour to meet different production needs. The material can be selected from carbon steel, 304/316L stainless steel or PP plastic bucket, which is corrosion-resistant and easy to clean, especially suitable for conveying food-grade or high-purity plastic pellets.

As a key equipment in the plastic processing production line, our Bucket Elevator for Plastic Pellets can customize solutions according to the characteristics of different plastic particles (particle size, specific gravity, fluidity) by optimizing the barrel, designing self-lubricating chains, gravity tensioning devices, reducing the running speed, and using anti-static materials. It can easily solve the problems of material jamming, dust leakage and wear. The equipment adopts a closed structure to effectively prevent dust pollution and external impurities from mixing into plastic particles during transportation.

What types of Bucket Elevator for Plastic Pellets are there?

Bucket Elevator for Plastic Pellets is mainly divided into four types according to transmission mode and structural characteristics: TD series belt type, TH series chain type, NE series plate chain type, and Z type. The model can be selected according to the type of material to be conveyed and the application scenario.

TD series belt bucket elevator for plastic pellets: adopts rubber belt transmission, runs smoothly and quietly, suitable for conveying ordinary plastic pellets with a temperature not exceeding 60℃, with a processing capacity of 2-50 tons/hour and a lifting height of up to 40 meters.

TH series chain bucket elevator for plastic pellets: adopts forged chain transmission, with high mechanical strength, suitable for conveying plastic pellets with a larger specific gravity or where a higher lifting height is required, with a processing capacity of 10-100 tons/hour and a lifting height of up to 50 meters.

NE series plate chain bucket elevator for plastic pellets: adopts plate chain transmission, with high lifting efficiency, suitable for large-scale continuous production, with a processing capacity of 30-300 tons/hour and a lifting height of up to 80 meters, which is an ideal choice for large plastic processing enterprises.

Z-type bucket elevator for plastic pellets: special steering design, suitable for occasions with limited space or the need to change the conveying direction, with a processing capacity of 2-20 tons/hour and a lifting height generally within 30 meters, widely used in small plastic product factories and packaging lines.

According to the hopper capacity, our plastic pellet bucket elevator can also be divided into different models such as 1.0L, 1.8L, 3.8L and 6.5L to meet different production requirements.

What are the advantages of Bucket Elevator for Plastic Pellets?

Bucket Elevator for Plastic Pellets not only has large output, low energy consumption and flexible configuration when conveying plastic pellets, but also optimizes the hopper structure and unloading method according to the characteristics of plastic pellets to ensure that the plastic pellets are not broken during the conveying process, as follows:

No crushing design: Specially optimized hopper structure and unloading method to ensure that the plastic pellets are almost free of collision and extrusion during the conveying process, maintain the integrity of the pellets, and reduce the scrap rate to less than 0.5%.

Sealed and dustproof: Fully enclosed structure design, equipped with plexiglass observation window, effectively prevents the spillage of plastic pellet dust; silicone sealing strips are used in key parts, and the dustproof level reaches IP54 standard

Flexible configuration: Provide a variety of hopper materials such as stainless steel, carbon steel and food-grade ABS; explosion-proof motors, forced ventilation systems or automatic cleaning devices can be configured as needed to meet special working conditions.

Low energy consumption: The variable frequency drive technology can automatically adjust the operating speed according to the actual load, which can save 15%-20% of electricity compared with the fixed speed model, greatly reducing the operating cost.

What is the principle of Bucket Elevator for Plastic Pellets?

When Bucket Elevator for Plastic Pellets is working, the plastic particles flow evenly into the bottom hopper through the vibrating feeder, and the motor drives the sprocket or pulley through the reducer to drive the traction member (chain or belt) equipped with the hopper to rise vertically, lifting the plastic particles from the bottom to the required height. When the hopper reaches the top, the plastic particles are discharged by centrifugal force or gravity, and flow into the designated receiving device through the guide groove. The empty hopper bypasses the top wheel and rotates downward, returning to the bottom to prepare for the next loading, completing a working cycle.

Parameters of Bucket Elevator for Plastic Pellets

| Parameter category | TD series | TH series | NE series | Z/C type |

| Processing capacity | 2-50m³/h | 10-100m³/h | 30-300m³/h | 2-20m³/h |

| Lifting height | 3-30m | 10-50m | 20-80m | 3-15m |

| Applicable particle size | 0.5-10mm | 1-20mm | 2-20mm | 0.5-15mm |

| Hopper capacity | 1.0-3.8L | 3.8-6.5L | 6.5-12L | 1.0-3.8L |

|

Running speed |

1.2-1.8m/s | 0.8-1.5m/s | 0.5-1.2m/s | 0.4-0.8m/s |

| Motor power | 1.5-15kW | 5.5-30kW | 11-75kW | 0.75-7.5kW |

| Body material | Carbon steel/stainless steel | Carbon steel/stainless steel | Carbon steel/stainless steel | Stainless steel/carbon steel/PP |

| Hopper material | ABS/PP/stainless steel | Stainless steel/carbon steel | Stainless steel/wear-resistant steel | ABS/PP/stainless steel |

For special plastic pellets (such as high-temperature materials, materials prone to static electricity, etc.), we can provide the following customized solutions:

High temperature resistant type: can withstand a maximum material temperature of 120°C (using heat-resistant tape or special chain)

Anti-static type: equipped with a static conductive system and explosion-proof motor, suitable for plastic pellets prone to static electricity

Food grade type: all stainless steel structure + food grade hopper, in line with FDA certification requirements.

What is the purpose of Bucket Elevator for Plastic Pellets?

Bucket Elevator for Plastic Pellets can be used to vertically lift various plastic pellets with a particle size between 0.5-20mm from a low place to a specified height, including recycled plastic pellets, new material pellets and various modified plastic pellets, etc., which are often used in plastic raw material production, plastic product processing, modified plastic production, recycled plastic processing and packaging and warehousing and other plastic application scenarios.

Bucket Elevator for Plastic Pellets Customer Case

| Application scenario | Lifting height | Lifting amount | Motor power | Equipment type | Remarks |

| Chemical industry (PP/PE particle conveying) | 15 meters | 25m³/h | 5.5kW | Stainless steel bucket elevator | Made of 304 stainless steel, fully enclosed structure to prevent dust leakage 35 |

| Food grade plastic particles (PET bottle flakes) | 10 meters | 15m³/h | 3.7kW | Chain bucket elevator | Equipped with wear-resistant chain, low crushing rate design, in line with food hygiene standards13 |

| Recycled plastic particles (crushed material) | 20 meters | 40m³/h | 11kW | Plate chain bucket elevator | Suitable for high wear environments, the hopper is made of thickened steel plate, and the lifting height can be customized 18 |

How to select Bucket Elevator for Plastic Pellets?

Selection based on the characteristics of plastic particles: TD or TH series standard equipment can be used for ordinary PP/PE/PS particles; for fragile ABS/PC particles, low-speed Z/C type equipment should be used with special hoppers; high-temperature particles need to use equipment equipped with heat-resistant chains or tapes and increased heat dissipation design; particles that are prone to static electricity should use explosion-proof equipment and be equipped with a static conductive system; and food-grade particles require all-stainless steel equipment and food-grade hoppers.

Selection based on lifting capacity: When the lifting capacity is less than 5 tons/hour in small batch conditions, Z/C type bucket elevators are suitable; if it is in a medium-scale lifting capacity of 5-50 tons/hour, TD belt or TH chain elevators are more suitable; for large-scale operation scenarios with a lifting capacity of more than 50 tons/hour, NE plate chain elevators are required to ensure efficient transportation.

Choose according to the lifting height: When the lifting height is less than 15 meters, Z/C type or TD series equipment can be selected; if the lifting height is in the medium range of 15-40 meters, TH series equipment is a better choice; and for high-height lifting requirements exceeding 40 meters, NE series equipment is required to ensure stable and efficient completion of the lifting operation.