Bucket Elevator for Peanuts

It can be used to transport shelled/shelled/crushed peanuts vertically from low to a specified height without any damage during the whole process.

| Lifting height | 3-60 meters (customizable) |

| Transportation capacity | 3-100 tons/hour |

| Power | 3-30 kW |

| Hopper | Stainless steel and pp plastic |

| Hopper width | 100-1200mm, customizable |

What is Bucket Elevator for Peanuts?

Bucket Elevator for Peanuts is a vertical conveying equipment for lightweight granular materials such as peanuts. It can continuously and stably transport peanuts from low places (such as raw material warehouses) to high places (such as dryers, sorting machines or packaging lines), reduce manual handling, and improve production efficiency. The lifting height is usually 5-60 meters (customizable), and 3-100 tons of peanuts can be processed per hour. In terms of material, the hopper is made of food stainless steel or wear-resistant plastic to ensure hygiene and safety, and the casing can be made of carbon steel (sprayed plastic to prevent rust) or all-stainless steel structure to adapt to humid or high-cleaning environments. It is mainly used in peanut processing plants, food production lines and other occasions.

What types of Bucket Elevator for Peanuts are there?

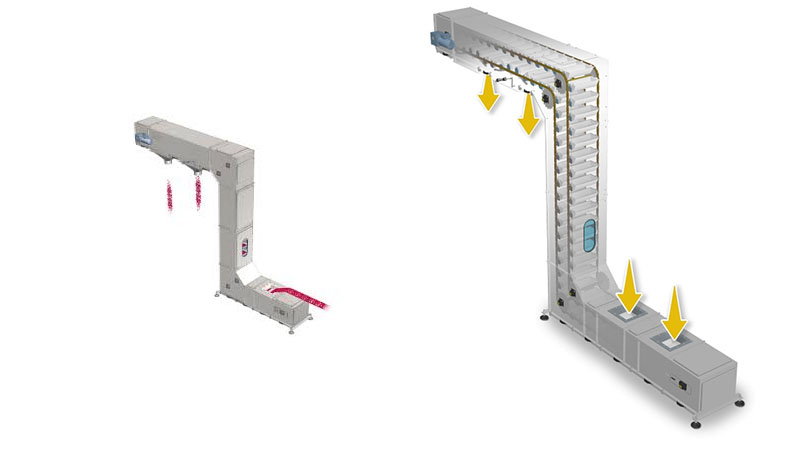

In response to the different needs of peanut processing, Bucket Elevator for Peanuts can be divided into Z-type and vertical types, which can be selected according to the characteristics of the peanuts to be transported and the application scenarios:

Z-type Bucket Elevator for Peanuts: Suitable for sites with limited space, it can realize horizontal-vertical-horizontal transportation, especially suitable for peanut packaging lines, color sorter feeding and other links, no crushing rate to ensure the integrity of peanuts, and the lifting height can reach 30 meters.

Vertical Bucket Elevator for Peanuts: Traditional vertical lifting design, lifting height up to 60 meters, large conveying capacity, suitable for large-scale vertical transportation of peanut raw materials.

What are the advantages of Bucket Elevator for Peanuts?

Bucket Elevator for Peanuts adopts inflow feeding and induced unloading design, which effectively reduces the collision and extrusion between peanuts during transportation and ensures the integrity of the material. The surface of the food-grade plastic hopper is smooth to avoid scratches on the surface of peanuts, the crushing rate is less than 0.5%, and with the special unloading angle design, complete unloading and no return of materials can be achieved. The equipment has a conveying capacity ranging from 6m³/h to 400m³/h, which can meet the needs of production of different scales. The lifting height can reach up to 80 meters, which is suitable for multi-story factories and equipped with variable frequency speed regulation function to realize flexible adjustment of conveying speed. In terms of operation, the rubber-coated design of the head wheel prevents the bucket belt from slipping and deviating, the machine base buffer device reduces vibration and foreign matter intrusion, and the specially treated high-strength traction parts (chain/belt) have a service life of 3-5 years. The fully enclosed structure prevents dust leakage, and food-grade materials ensure hygiene and safety. At the same time, multiple protection devices such as overheating and overload are configured to ensure stable and reliable operation of the equipment.

What is the working principle of Bucket Elevator for Peanuts?

Peanuts enter the bottom of Bucket Elevator for Peanuts from the feed port and enter the hopper through inflow feeding or digging feeding. The motor drives the head wheel to rotate through the reducer, driving the traction member (belt or chain) equipped with the hopper to rise vertically. When the hopper reaches the top, the peanuts are thrown out by centrifugal force or gravity and discharged from the discharge port. The empty hopper after discharge returns to the bottom along the other side, completing a working cycle.

Bucket Elevator for Peanuts Parameters

| Model | Bucket width (mm) | Conveying capacity (m/h) | Lifting height (m) | Power (kW) | Applicable peanut type | Reference price (yuan) |

| TD140 | 140 | 6 | ≤80 | 1.5-3 | Peanuts, crushed peanuts | $400 and up |

| TD160 | 160 | 8-10 | ≤80 | 2.2-4 | Small and medium peanut kernels | $620 and up |

| TD180 | 180 | 12-15 | ≤80 | 3-5.5 | Standard peanut kernels | Starting from $700 |

| TD200 | 200 | 15-20 | ≤80 | 4-7.5 | Large peanuts, peanuts in shells | Starting from $800 |

| TD250 | 250 | 22-26 | ≤80 | 5.5-11 | Peanuts in shells, peanut mixture | $980 up |

| TD400 | 400 | 50-60 | ≤80 | 11-18.5 | High-yield peanut raw material transportation | $1700 up |

| TD630 | 630 | 90-120 | ≤80 | 18.5-30 | Large peanut processing plant | $5200 up |

| Z type | Customized | 5-30 | ≤15 | 0.75-22 | Peanut packaging, color sorting and feeding | Negotiable |

What is the application industry of Bucket Elevator for Peanuts?

Bucket Elevator for Peanuts can efficiently transport shelled peanuts, shelled peanut kernels, peanut crumbs and semi-finished products, and is suitable for the following core scenarios:

Raw material pretreatment: Vertically transport shelled peanuts from the storage area to the cleaning, sorting or shelling equipment, with a processing capacity of 5-50 tons/hour, reducing manual handling losses.

Processing line: In the baking plant or oil press workshop, continuously lift the peanut kernels to the roaster, press or packaging line, and the temperature resistance design is suitable for environments below 80°C.

Storage and transportation: Transport the finished peanut kernels/crushed grains to the silo or truck loading and unloading port, equipped with an anti-breakage hopper (polyethylene or stainless steel), with a breakage rate of <0.5%.

Bucket Elevator for Peanuts customer case

| Customer name | Project content | Equipment configuration | Effect |

| Qingdao Grain and Oil Group | Peanut shelling-grading-color sorting-packaging fully automatic production line | 3 TD250 steel bucket chain elevators, 2 Z-type elevators | Daily processing capacity reaches 1,000 tons, lifting height 25 meters, conveying capacity 26m³/h |

| A US International Trade Co., Ltd. | Peanut export processing line | 4 TD200 plastic bucket belt elevators | Daily processing capacity 800 tons, peanut crushing rate <0.3%, far exceeding the industry standard |

| A large peanut food factory in Indonesia | Transformation of roasted peanut production line | 6 Z-type fully enclosed stainless steel elevators | Achieve stable transportation in high temperature environment (120°C), and increase production capacity by 35% |

| A peanut oil production enterprise in Laos | Peanut pre-processing workshop | 2 TD400 steel bucket plate chain elevators | Processing of shelled peanuts 60m³/h, lifting height 50 meters, running for 3 years without major repairs |

| A peanut export enterprise in Southeast Asia | New peanut processing plant | TD630 ring chain elevator system | Hourly processing capacity 120m³, meeting EU food hygiene standards |