Bucket Elevator for Oats

Vertical conveying of oatmeal, oat grains and oat powder from low to high

| Lifting height | 3-60 meters (customizable) |

| Conveying capacity | 5~100 cubic meters/hour |

| Power | 0.45-10 kW |

| Hopper | Food grade PP plastic or polished stainless steel |

What is Bucket Elevator for Oats?

Bucket Elevator for Oats is a vertical conveying equipment for oat products in various forms, such as oat flakes, oat grains, and oat powder. It drives the hopper through a ring chain or belt to lift the oats from a low place to a high place, which can realize continuous and efficient vertical conveying of oats. The lifting height is usually 5-30 meters, and the lifting capacity is 10-100 tons/hour. It is widely used in grain processing, warehousing and feed production lines. The hopper material is mostly made of food-grade stainless steel (304/316) or wear-resistant engineering plastics to ensure hygiene and corrosion resistance and avoid oat contamination.

What types of Bucket Elevator for Oats are there?

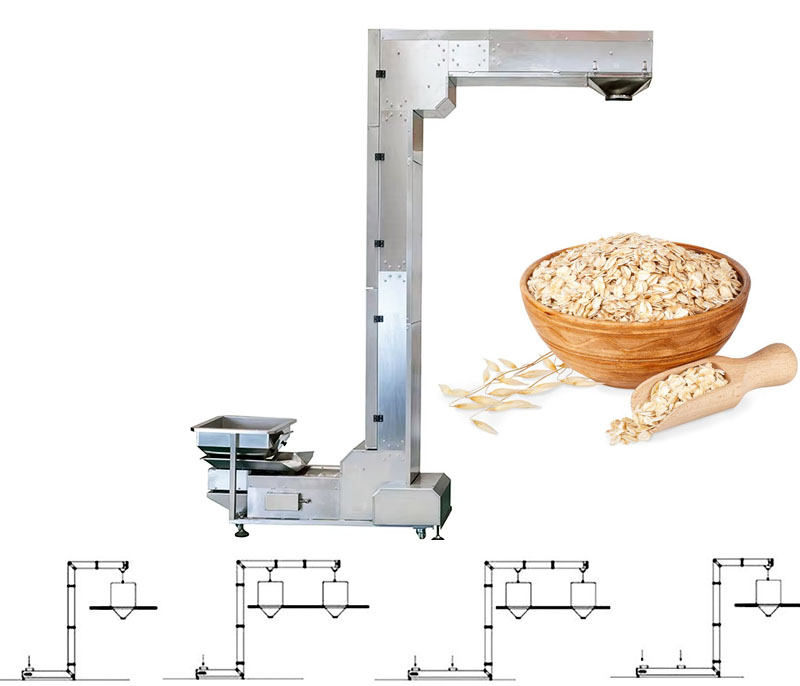

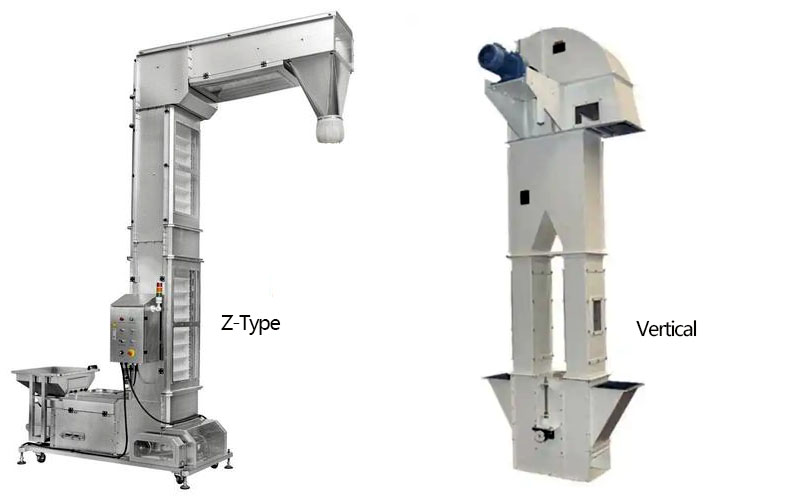

Bucket Elevator for Oats has two types: Z-type and vertical, which can be selected according to the type of oats to be transported and the application scenario.

Z-type Bucket Elevator for Oats: It adopts horizontal-vertical-horizontal combined conveying, which can replace the traditional three equipments. It has a compact structure and is suitable for factories with limited space. It can be used for oatmeal production lines and packaging machine feeding systems. It has a seamless hopper design to prevent oats from spilling.

Vertical Bucket Elevator for Oats: It adopts pure vertical conveying, with a lifting height of up to 60 meters, large conveying capacity, stable operation, and is suitable for large oat processing plants and grain storage.

What are the advantages of Bucket Elevator for Oats?

The surface of oat particles is smooth but the texture is fragile. It is very easy to break due to collision and extrusion during the conveying process. Ordinary conveying equipment not only has a high breakage rate, but also has the risk of dust explosion and cross contamination. To address these issues, our Bucket Elevator for Oats uses a specially designed hopper and low-speed operation mode to achieve gentle conveying, keeping the crushing rate below 0.5%; the single lifting height can reach 40 meters (some models can reach 80 meters), effectively solving the space limitations of the plant; the conveying capacity covers 100kg/h to 90m³/h, which can meet the different needs from small processing plants to large production lines; at the same time, all contact parts are made of 304 stainless steel or food-grade PP plastic, which fully complies with food safety standards, and the closed structure design effectively reduces dust spillage to ensure safe and efficient production.

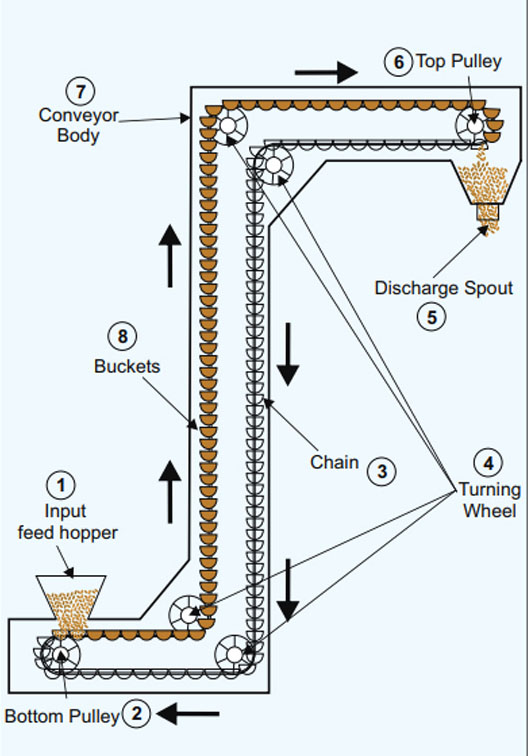

How does Bucket Elevator for Oats work?

Bucket Elevator for Oats realizes vertical material conveying through a circulating hopper: when oats evenly enter the hopper from the bottom feed port, the hopper rises vertically with the traction member (chain or belt), and after reaching the top, the unloading is completed by centrifugal force or gravity, and the empty hopper returns to the bottom along the other side to continue the cycle.

Bucket Elevator for Oats parameters

| Model | ZD-160 | ZD-250 | ZD-330 | ZD-400 | ZD-500 | ZD-530 | ZD-650 | ZD-800 |

| Capacity(m3/h) | 2.9-4.8 | 4.6-15.7 | 6.0-10.0 | 15.2-25.2 | 25.4-42.3 | 20-33.4 | 32.9-54.9 | 40.6-67.6 |

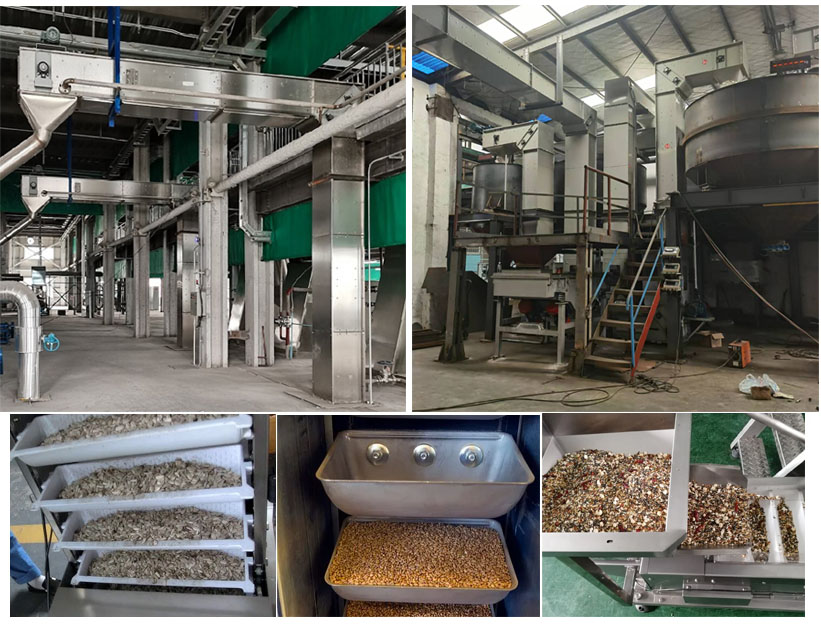

What are the applications of Bucket Elevator for Oats?

Oatmeal bucket elevator is suitable for vertical transportation of various forms of materials such as whole oats, oatmeal, oatmeal powder, etc. The main application scenarios include: the storage, outbound and in-warehouse transportation of oatmeal raw materials in grain storage; the transportation between processes in oatmeal, oatmeal milk, oatmeal powder and other production lines in food processing; the transportation of oatmeal raw materials to the mixing or packaging section in feed production; the transportation of oatmeal hulls and other by-products in bioenergy for fuel processing.