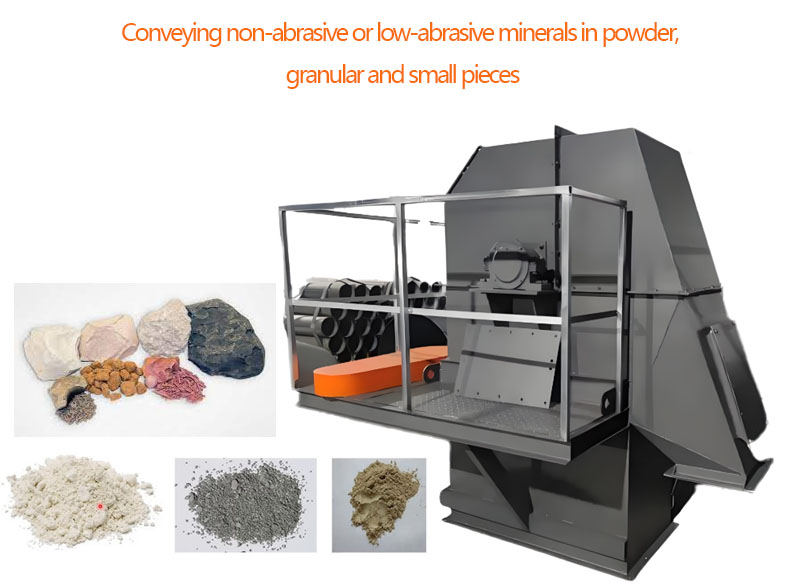

Bucket Elevator for Minerals

Realize efficient transportation of powdered, granular and small block mineral materials from low to high

| Transportation capacity | 15m³/h-800m³/h |

| Lifting height | 4-80mi |

| Motor power | 3-75KW |

| Hopper volume | 1.8-42L |

| Material temperature | 250℃ |

| Equipment material | Manganese steel, stainless steel 304/316L (optional) |

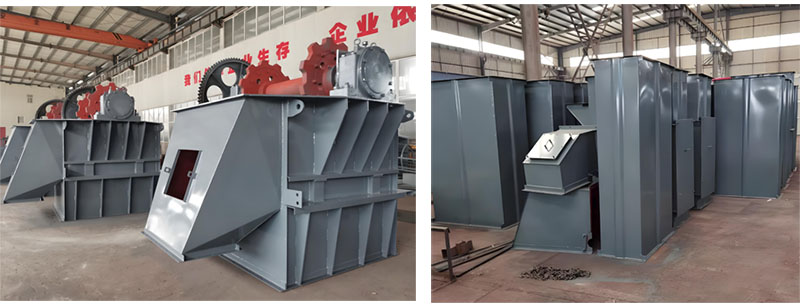

What is Bucket Elevator for Minerals?

Bucket Elevator for Minerals is a device that realizes vertical or large-angle transportation of minerals by means of the linkage between the hopper and the traction component (chain or belt). It can vertically transport various loose minerals such as coal, ore, limestone, coke, etc. Whether it is powder, granular or small block materials, it can be stably transported. Its lifting height can reach more than 80 meters, and the lifting capacity per hour can reach up to 800 tons, which can be flexibly adjusted according to working conditions. The hopper can be shallow, deep or bottomless to adapt to different material characteristics. For example, the deep hopper is suitable for conveying dry and fluid minerals, while the shallow hopper is more suitable for wet and easy-to-cake materials.

Bucket Elevator for Minerals can accurately solve the efficiency problem in the vertical transportation of minerals: avoid the scattering loss of traditional chute transportation, break through the terrain restrictions to achieve high-altitude operations, and the closed transportation can reduce dust pollution. It can be matched with an automated control system to improve production continuity. It is an indispensable "vertical transportation expert" in the efficient production of mines.

What types of Bucket Elevator for Minerals are there?

Bucket Elevator for Minerals can be divided into three types: chain type, plate chain type and belt type according to the different traction mechanisms, unloading methods and hopper forms. Each type is designed for different mineral characteristics and process requirements to ensure optimal conveying performance under various working conditions.

| Type | Traction mechanism | Applicable minerals | Maximum lifting height | Temperature limit | Typical model |

| Ring chain (TH) | Ring chain | Abrasive ore and slag | 40 meters | 250℃ | TH200、TH350 |

| Plate chain (NE) | Steel plate chain | High density, bulk minerals | 80 meters | 200℃ | NE100、NE300 |

| Belt type (TD) | Rubber belt | Non-abrasive powdered minerals | 50 meters | 80℃ | TD160、TD250 |

What are the advantages of Bucket Elevator for Minerals?

Compared with other vertical conveying equipment, Bucket Elevator for Minerals has significant advantages and can effectively solve various problems in the process of mineral transportation. These advantages make it the preferred conveying equipment in the mining, cement, metallurgy and other industries.

Wide range of lifting heights: low chain speed design, stable operation, lifting height up to 30-80 meters. The plate chain elevator can lift up to 60 meters at rated conveying capacity, meeting the height requirements of most mineral processing plants.

Strong conveying capacity: large-capacity hoppers are densely arranged, with a lifting capacity of 15-800m³/h to meet the needs of production of different scales. The low chain speed design (usually 0.8-1.25m/s) ensures conveying efficiency and reduces wear and material breakage.

Strong material adaptability: It can handle various forms of minerals from fine powder to small pieces, such as coal powder (0-5mm), cement (0-3mm), ore (0-50mm), etc. The special design can convey high-temperature materials with a temperature of up to 250℃.

Sealed and environmentally friendly: fully enclosed structure design effectively prevents dust spillage and meets environmental protection requirements

Performance comparison between Bucket Elevator for Minerals and traditional conveying equipment

| Performance indicators | Bucket Elevator for Minerals | Ordinary bucket elevator | Belt conveyor | Screw conveyor |

| Maximum lifting height | 80 meters | 40 meters | 20 meters (inclination <20°) | 20 meters |

| Conveying capacity range | 15-800m³/h | 10-300m³/h | 5-200m³/h | 5-100m³/h |

| Wear resistance | Excellent (special wear resistance treatment) | General | Poor | Medium |

| Sealing performance | Excellent (fully enclosed design) | Good | Poor | Excellent |

| Energy consumption ratio | 1.0 (benchmark) | 1.2-1.5 | 1.5-2.0 | 2.0-3.0 |

| Applicable temperature | ≤250℃ | ≤120℃ | ≤80℃ | ≤200℃ |

How does Bucket Elevator for Minerals work?

When Bucket Elevator for Minerals is working, the bucket circulates around the drive wheel and the tension wheel with the traction chain or belt. The material enters from the bottom feed port, is scooped or loaded into the bucket, and moves upward to the top with the elevator. The material is discharged from the discharge port through centrifugal, gravity or mixed unloading methods, completing the vertical transportation of minerals from low to high. The whole process is continuous and efficient, and the operating speed and unloading method can be adjusted according to the characteristics of the material.

Bucket Elevator for Minerals Parameters

| Model | Traction type | Hopper volume (L) | Conveying capacity (m³/h) | Applicable minerals |

| TH160 | Ring chain | 1.8-3.2 | 8-21 | Coal powder, mineral powder |

| TH200 | Ring chain type | 3.5-7.5 | 15-42 | Cement, ore |

| TH350 | Ring chain type | 7.5-15 | 42-69 | Slag, crushed stone |

| NE30 | Plate chain type | 2.1-4.2 | 15-30 | Powdered minerals |

| NE100 | Plate chain | 7-14 | 60-100 | Granular minerals |

| NE300 | Plate chain | 21-42 | 200-300 | Blocked minerals |

What are the applications of Bucket Elevator for Minerals?

Bucket Elevator for Minerals can be used to transport non-abrasive or low-abrasive powders, granules, small blocks and high-temperature materials with a particle size of 0-50mm, such as cement, lime powder, mineral powder, coal powder, sand, gravel, slag, coke, coal, ore, gypsum block, clay block, hot clinker, hot slag, etc. It is often used in mining, cement, metallurgy and other industries.

Recommended elevator types for mineral materials

| Mineral type | Typical materials | Recommended elevator type | Key requirements |

| Powdered minerals | Cement, mineral powder | TD type (belt type) | Good sealing, low crushing |

| Granular minerals | Sand, gravel, slag | NE type (plate chain) | Wear-resistant, large capacity |

| Block minerals | Ore, coal | TH type (ring chain) | Impact resistance, high strength |

| High temperature minerals | Clinker, calcined ore | High temperature resistant TH type | Heat-resistant material, heat dissipation design |

| Corrosive minerals | Salts, chemical ores | Stainless steel NE type | Anti-corrosion material |

| High-value minerals | Concentrate powder, micro powder | Fully sealed TD type | Leakage-proof, low residue |