Bucket Elevator for Millet

Vertical conveying of millet from low to high is achieved through the continuous operation of the hopper

| Lifting height | 5-60 meters |

| Lifting volume | 2-100t/h |

| Hopper volume | 1.2-10L |

| Lifting speed | 0.8-2.5m/s |

| Power | 1.5-30kW |

What is Bucket Elevator for Millet?

Bucket Elevator for Millet is a bucket elevator used for vertical conveying of small-particle, low-abrasive materials such as millet (millet grains). It uses a bucket fixed on the traction member to realize the automatic conveying of millet from low to high through continuous operation. The lifting height can reach 60 meters, and the conveying capacity is 2-100 tons per hour. Its core advantage lies in the anti-breakage, anti-splashing, and fully sealed dust-proof structure, which solves the problem of conveying loss caused by small particles (about 1-2mm in diameter) and strong fluidity of millet.

Unlike traditional bucket elevators, Bucket Elevator for Millet uses a shallow round bottom bucket to avoid material residue; the low-speed operation design (chain speed ≤1.5m/s) reduces the impact force and ensures that the integrity rate of millet is >99%

What are the categories of Bucket Elevator for Millet?

Bucket Elevator for Millet can be divided into three types: chain type, plate chain type and belt type. According to the different traction components and applicable scenarios, millet bucket elevators are mainly divided into three categories:

Chain type Bucket Elevator for Millet: It adopts high-strength alloy steel chain, good wear resistance, long service life, lifting height up to 30 meters, millet processing plants with large conveying capacity (maximum 50t/h).

Plate chain type Bucket Elevator for Millet: It adopts heavy steel plate chain with strong load-bearing capacity; it is suitable for heavy working conditions, such as lifting shelled millet or mixed materials; it has good impact resistance and is suitable for uneven feeding conditions

Belt type Bucket Elevator for Millet: It adopts food-grade rubber belt, runs smoothly and quietly, can be used in small and medium-sized millet processing enterprises, lifting height <15 meters, low cost, easy to clean, suitable for frequent changes of material varieties

What are the advantages of Bucket Elevator for Millet?

Bucket Elevator for Millet uses a vertical conveying structure that can save more than 50% of space. The lifting speed of 0.8-2.5m/s combined with the continuous operation mode can save more than 40% of energy compared to pneumatic conveying. In terms of quality assurance, the fully enclosed structure combined with the gentle conveying method can not only control the breakage rate below 0.5%, but also effectively prevent dust and moisture. The integrated dust removal module can meet food-grade cleanliness standards. The economic performance is a 6-12 month investment recovery period, a service life of more than 2 years for core components, and it supports modular transformation to adapt to different production capacity requirements. The maintenance cost is 30% lower than similar equipment.

How does Bucket Elevator for Millet work?

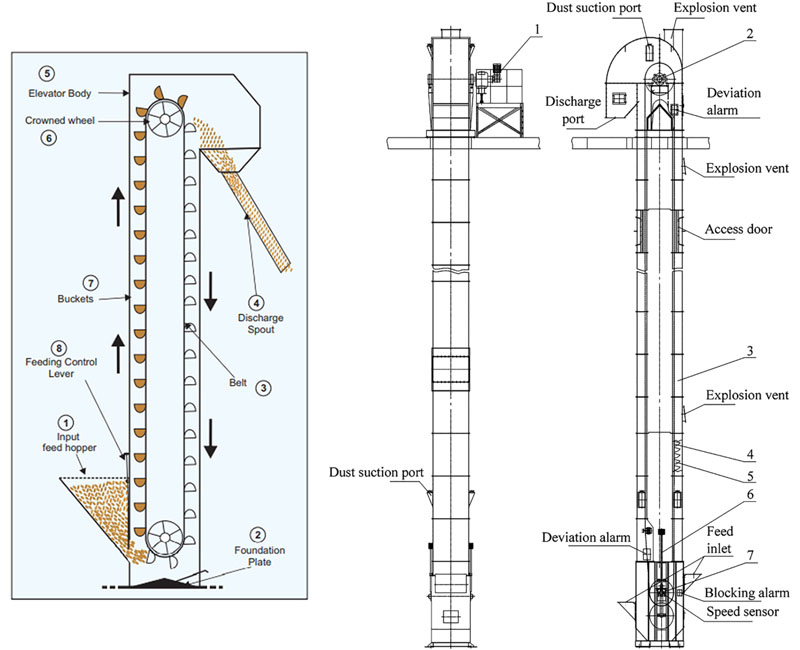

After the Bucket Elevator for Millet is started, the millet in the bottom storage hopper flows evenly into the running hopper through gravity or auxiliary feeding device. The hopper filled with millet rises vertically with the traction member (chain or belt). After reaching the top, the hopper bypasses the driving wheel and changes direction. Under the action of centrifugal force and gravity, an induction unloading design is adopted to ensure that the millet slides out smoothly, reducing impact and residue; the empty hopper returns to the bottom along the downward side to complete a working cycle.

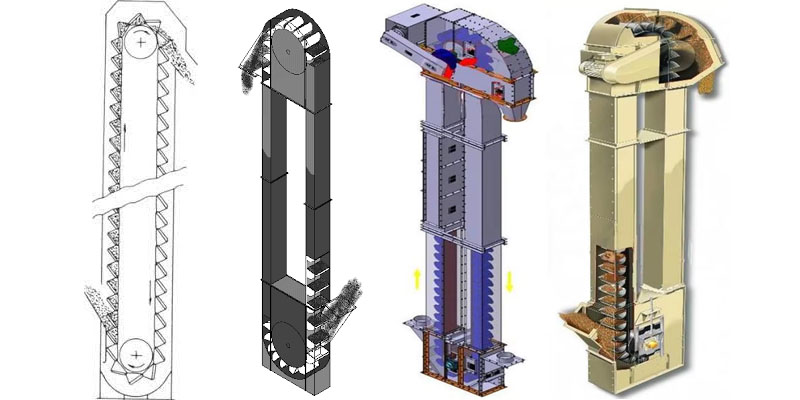

What are the structural components of Bucket Elevator for Millet?

The structure of Bucket Elevator for Millet includes: hopper, traction chain, motor, backstop brake, observation window, inspection door and dust removal interface, etc.

Anti-spill hopper: 2mm thick stainless steel stamping, edge curling to prevent hooking

Traction chain: alloy steel forging, wear-resistant life> 20,000 hours

Explosion-proof motor: IP54 protection level, suitable for dust environment

Reverse brake device: prevents blockage caused by reverse rotation when power is off

Observation window + maintenance door: quick troubleshooting, maintenance without disassembly

Dust removal interface: negative pressure air intake port reserved on the top, compatible with factory dust removal system

What are the applications of Bucket Elevator for Millet?

Bucket Elevator for Millet can realize the vertical transportation of millet from low to customized high, which is often used in millet processing production line to lift raw grain to stone removal machine after initial cleaning, polishing millet to color sorter and finished millet to packaging machine, etc.; bulk millet in warehouse lifting, out of warehouse loading lifting system in millet storage; and millet flour production material lifting in millet deep processing, millet wine brewing raw material transportation and puffed millet food production line, etc.

Bucket Elevator for Millet Customer Case

| Case | Problem/Requirement | Solution | Effect |

| Organic millet processing plant in Southeast Asia | High crushing rate of screw conveyor (>3%), insufficient processing capacity | Customized 10-meter high belt elevator with anti-crushing hopper | Crushing rate reduced to 0.3%, production capacity increased by 2 times, energy consumption reduced by 35% |

| China Millet Deep Processing Park | Multiple varieties of millet are transported independently to avoid mixing | 3 parallel plate chain elevators with automatic distribution system | Accurate diversion of 5 kinds of millet with zero cross contamination |

| Large-scale millet storage center in Northeast China | Low reliability of transportation under low temperature environment of -25℃ | Using special low-temperature chain + motor with heating casing | Fail-free operation throughout the year to meet the storage throughput demand of 100,000 tons/year |