Bucket Elevator for Malt

Efficiently and gently lift malt vertically from low to high

| Lifting height | 3-60 meters (customizable) |

| Conveying capacity | 3-400 tons/hour |

| Power | 3-160 kW |

| Hopper capacity | 2-25L |

| Operating speed | 0.5-1.25m/s |

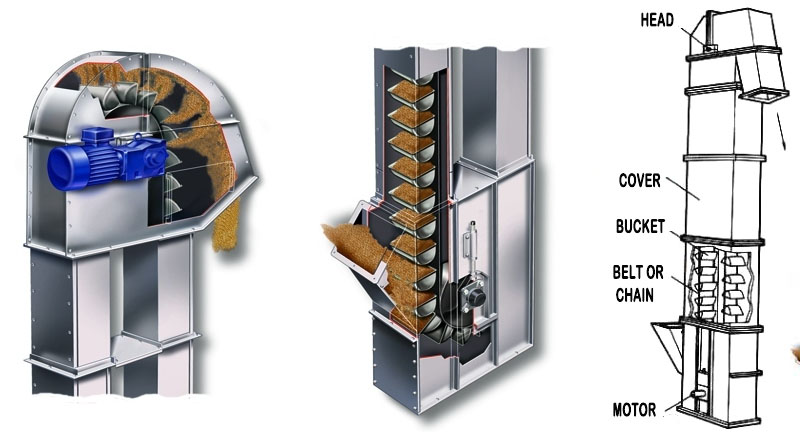

What is Bucket Elevator for Malt?

Bucket Elevator for Malt is a vertical lifting device designed for malt transportation. It is made of wear-resistant alloy steel chain or food-grade stainless steel, and can withstand high temperatures of 250°C. It can efficiently and low-crush the dried malt from a low position (such as the dryer outlet) to a high position (such as storage or processing equipment) to avoid mechanical extrusion and damage to the malt particles. The lifting height is usually 5~60 meters, and the lifting capacity can reach 5~400m³/h. The specific parameters can be adjusted according to the characteristics of the malt (such as humidity and particle size). The equipment adopts inflow feeding and induction unloading to reduce the crushing rate, and can be equipped with an optional sealed casing to prevent dust. It is suitable for food industry scenarios such as beer brewing and maltose production.

Why choose Bucket Elevator for Malt?

Bucket Elevator for Malt is specially designed for malt. It adopts alloy steel forged chain, which can withstand temperatures up to 250℃ and can effectively transport high-temperature malt after drying. Its unique inflow feeding and induction unloading design, with a running speed of 1-1.25m/s, can avoid mechanical extrusion caused by hopper digging to the maximum extent, achieve low crushing transportation, and maintain the integrity of malt. To meet the requirements of food production, stainless steel hopper and sealed casing can be selected to effectively prevent dust leakage and ensure compliance with HACCP regulations.

What types of Bucket Elevator for Malt are there?

Bucket Elevator for Malt can be divided into TH chain type, NE plate chain type and Z type according to the characteristics of malt and production capacity requirements:

TH chain type Bucket Elevator for Malt: It can be used to lift dry malt (moisture content <12%) and roasted malt, with a lifting height of 50 meters, which can meet the vertical transportation of multi-story factories and a conveying capacity of 35-365m³/h (about 8-80 tons/hour).

Hopper configuration: SH deep hopper (dry malt such as light beer malt, strong throwing force, 30% increase in conveying volume, ZH medium deep hopper (sticky malt such as high-protein wheat malt, anti-caking residue).

NE plate chain Bucket Elevator for Malt: plate chain structure is impact-resistant, supports single bucket load ≥1kg, fully sealed casing, anti-wet hot steam corrosion, suitable for high-temperature roasted malt (such as chocolate malt), large conveying production line

Z-type Bucket Elevator for Malt adopts horizontal-vertical multi-directional conveying, adapts to complex space, modified plastic hopper, zero metal contamination risk, suitable for precise feeding and small batch processing, such as malt sampling, small craft brewery, color sorter feeding

What is the working principle of Bucket Elevator for Malt?

Bucket Elevator for Malt realizes vertical transportation of malt under the coordinated action of the continuous cycle traction mechanism and hopper: malt flows evenly into the bottom of the elevator from the feed port, and the rotating hopper "scoops" the malt at the bottom (scooping loading) or the malt directly "flows" into the hopper (inflow feeding). The hopper filled with malt rises vertically with the traction member (chain or belt) and runs smoothly in the closed barrel to avoid malt spilling and contamination. After the hopper reaches the top, the malt is thrown out by centrifugal force, gravity or a combination of the two (mixed unloading) and introduced into the next process through the unloading port; the empty hopper descends back to the bottom along the other side to complete a working cycle

Bucket Elevator for Malt Parameters

| Model | Lifting height (m) | Conveying capacity (m/h) | Material diameter (mm) | Hopper capacity (L) | Power (kW) |

| TH160 | 32 | 8 | 30 | 2 | 3.0 |

| TH200 | 36 | 15 | 30 | 3 | 5.5 |

| TH250 | 36 | 18 | 40 | 4 | 7.5 |

| TH300 | 36 | 27 | 40 | 4.4 | 11 |

| TH350 | 36 | 32 | 40 | 5.2 | 15 |

| TH400 | 36 | 42 | 50 | 6.3 | 18.5 |

| TH450 | 36 | 48 | 50 | 7.5 | 22 |

What are the applications of Bucket Elevator for Malt?

Bucket Elevator for Malt is suitable for conveying various types of malt, including kiln malt (high temperature state after drying), crystallized malt (caramel/caramel malt), roasted malt (dark malt) and ordinary basic malt (such as barley malt, wheat malt). Its low crushing design is particularly suitable for fragile specialty malts (such as chocolate malt, dark malt), ensuring the integrity of particles. It is often used in beer brewing, maltose production and food processing industries to transport malt from the dryer to the storage bin, from the storage bin to the saccharification tank, or transfer between different processing steps to meet the needs of efficient and hygienic continuous production.

Bucket Elevator for Malt Manufacturers