Bucket Elevator for Limestone

It is used for vertical conveying of lump, granular and powdered limestone, with the material temperature reaching up to 250℃.

| Model | NE15, NE30, NE50, NE150, NE200, NE300, NE400, NE500, NE600, NE800. |

| Lift amount | 15-800m³/h |

| Lifting height | 2-60m |

| Motor power | 3-160KW |

| Hopper type | Deep bucket/shallow bucket/wear-resistant lining hopper |

What is Bucket Elevator for Limestone?

Bucket Elevator for Limestone is a bucket elevator used for vertical transportation of blocky and abrasive materials such as limestone. It uses high-strength traction chains (loop chains or plate chains) and wear-resistant buckets to transport large and medium-sized limestone, limestone clinker and limestone powder materials with high abrasiveness from low to high, up to 60 meters. The working temperature can reach 250℃, and the hourly conveying capacity can reach 800m³/h, which can effectively solve the material lifting from mines to kilns.

Bucket Elevator for Limestone adopts wear-resistant alloy steel chain and automatic tensioning device, which effectively solves the common problems of traditional elevators in limestone transportation, such as chain breakage, fast bucket wear, and material jamming. According to the characteristics of limestone, gravity unloading mode, NE plate chain type or TH ring chain type with inflow loading can be selected, and deep bucket (SH type) or sharp-angle bucket with guide edge can be equipped to ensure smooth transportation of large pieces of material and reduce wear.

What are the types of Bucket Elevator for Limestone?

According to the physical properties and production process requirements of limestone, we provide various types of Bucket Elevator for Limestone such as NE plate chain, TH ring chain, TD belt type, etc., to ensure that each limestone material can get the best conveying solution.

NE Plate Chain Bucket Elevator for Limestone: Designed for medium and large blocks and abrasive limestone, it uses high-quality alloy steel high-strength plate chain, which is wear-resistant and reliable. There are 11 models from NE15 to NE800, with a lifting capacity of 15-800m³/h, which is the first choice for handling block limestone.

TH Ring Chain Bucket Elevator for Limestone: Suitable for powdered and small-particle limestone, it uses cast ring chain as the transmission part, has strong mechanical strength, larger lifting capacity and higher operating efficiency.

TD Belt Bucket Elevator for Limestone: Suitable for conveying small blocks and powdered low-abrasive limestone, with simple structure and stable operation, but the material temperature should not exceed 60℃ (ordinary belt) or 120℃ (heat-resistant belt)

Suggestions for selection according to limestone characteristics

| Limestone characteristics | Large limestone (particle size >50mm) | Granular limestone (particle size 5-50mm) | Powdered limestone (particle size <5mm) |

| Recommended models | NE200-NE800 | NE50-NE150 | NE15-NE30 |

| Hopper selection | Deep hopper (S method), increased spacing | Medium hopper, standard spacing | Shallow hopper (Q method), dense arrangement |

| Special configuration | Heavy plate chain, grille installed at the feed inlet | Double-row chain design, anti-return device | Fully sealed casing, explosion-proof design |

What are the advantages of Bucket Elevator for Limestone?

Bucket Elevator for Limestone has improved the wear resistance and energy saving of the equipment according to the characteristics of limestone. The following are the specific advantages:

Wear resistance: In view of the high abrasiveness of limestone, key components are specially treated. The chain plate is made of 45# steel quenching treatment (HRC36-42), and the upper and lower sprockets are made of ZG310-570 overall quenching and tempering and tooth surface quenching (HRC40-48). The wear resistance is more than 3 times higher than that of ordinary materials. The edge of the hopper is strengthened, which greatly extends the service life in the highly abrasive limestone environment.

Energy-saving design: Bucket Elevator for Limestone adopts inflow feeding and gravity unloading, avoiding the high energy consumption of traditional bucket loading. Fully enclosed casing design, optimized chain speed (0.4-1.2m/s), no material return phenomenon, and reactive power loss is reduced by more than 30%. Compared with similar products, energy consumption is reduced by 15-20%, and long-term operation can save a lot of electricity bills.

Superior adaptability: It can handle limestone materials in various forms, from large pieces (up to 270mm) to fine powder, from dry to slightly wet, and the temperature range covers room temperature to 250°C. The equipment has good sealing, effectively preventing limestone dust from spilling out, and making the working environment cleaner. The special anti-stuck design makes the equipment more tolerant when encountering jams caused by accidental factors, protecting key components from damage

Comparison of the performance of NE series and traditional elevators in limestone transportation

| Comparison item | NE series Bucket Elevator for Limestone | Traditional bucket elevator |

| Wear life | More than 5 years | 2-3 years |

| Unit energy consumption | 0.5-0.8kW·h/t | 0.8-1.2kW·h/t |

| Maintenance cycle | 6-12 months | 3-6 months |

| Applicable temperature | ≤250℃ | ≤120℃ |

| Noise level | <75dB | >85dB |

| Dust control | Fully sealed, less dust leakage | Open, dusty |

How does Bucket Elevator for Limestone work?

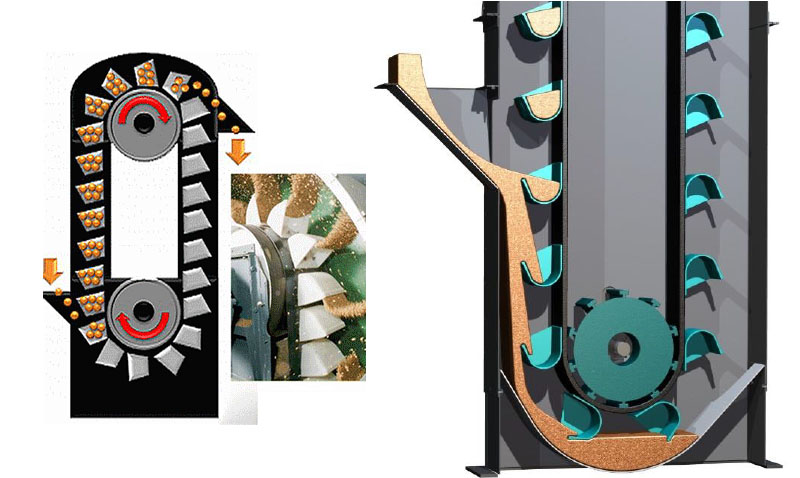

Bucket Elevator for Limestone lifts materials vertically from a low place to the required height through a continuously circulating hopper. Limestone materials are evenly fed into the bottom feed port of the elevator through a vibrating feeder or chute. The hopper filled with limestone is pulled vertically up by a high-strength plate chain. During the lifting process, the middle section track prevents the chain from swinging, ensuring that the limestone material is stably lifted without spilling. When the hopper runs to the top sprocket, it uses centrifugal force or gravity to unload the material, and the empty hopper returns to the bottom along the non-working branch.

Bucket Elevator for Limestone Parameters

| Model | Lifting capacity (m/h) | Applicable limestone block size (mm) | Maximum lifting height (m) | Power range (kW) | Chain type |

| NE15 | 15 | ≤65 | 30 | 1.5-3.0 | Single-row chain |

| NE30 | 32 | ≤90 | 35 | 3.0-5.5 | Single-row chain |

| NE50 | 60 | ≤90 | 40 | 5.5-11 | Double-row chain |

| NE100 | 110 | ≤130 | 45 | 11-18.5 | Double row chain |

| NE150 | 170 | ≤130 | 50 | 18.5-30 | Double row chain |

| NE200 | 210 | ≤170 | 50 | 22-37 | Double-row chain |

| NE300 | 320 | ≤170 | 50 | 30-55 | Double-row chain |

| NE400 | 360 | ≤205 | 50 | 37-75 | Double-row chain |

| NE500 | 470 | ≤240 | 60 | 45-90 | Double-row chain |

| NE600 | 600 | ≤240 | 60 | 55-110 | Double-row chain |

| NE800 | 800 | ≤270 | 60 | 75-132 | Double-row chain |

Note: The actual lifting volume is affected by factors such as limestone bulk density, particle size distribution, and moisture content.

What are the applications of Bucket Elevator for Limestone?

Bucket Elevator for Limestone can lift limestone in block (50 - 300mm), granular (5 - 50mm) and powder (less than 5mm), covering different processing states such as raw ore, crushed material and limestone powder. It has a wide range of application scenarios, including raw material and finished product transportation in cement production; lifting raw ore blocks and connecting crushing processes during mining; conveying aggregates and light calcium carbonate processing raw materials in the construction and building materials industry; lifting limestone powder in power plant desulfurization and other scenarios in the environmental protection field; as a slag-making agent conveying equipment for blast furnace ironmaking in the metallurgical industry; it can also be used for chemical raw material transportation, municipal engineering sewage treatment, etc., and can adapt to different working conditions according to material characteristics and production needs.

Bucket Elevator for Limestone Customer Case

| Application scenario | Lifting height | Lifting amount | Motor power | Equipment model/features | Special configuration |

| Lifting after initial crushing in limestone mines | 12m | 80-100t/h | 22kW | TH630 chain bucket elevator, manganese steel bucket | Dustproof sealing device |

| Cement plant raw material mill front lifting | 25m | 150t/h | 45kW | NE200 plate chain bucket elevator, wear-resistant lining | Anti-deviation alarm system |

| Lime kiln raw material conveying system | 18m | 50-60t/h | 18.5kW | TD500 belt bucket elevator, high temperature resistant belt | Temperature monitoring device |

| Desulfurization agent preparation workshop lifting | 8m | 30t/h | 11kW | Z-type bucket elevator, 304 stainless steel shell | Anti-corrosion treatment |