Bucket Elevator for Fly Ash

It is used to transport powdered and granular fly ash vertically from a low place to a high place, solving the dust and wear problems in fly ash transportation.

| Transportation capacity | 1-830 tons/hour |

| Lifting height | 3-60 meters |

| Motor power | 3-75kW |

| Hopper volume | 2-20L (standard type 5-10L, large capacity type 15-20L) |

| Material classification | Carbon steel (ordinary type), 304 stainless steel (anti-corrosion type), 316L stainless steel (high humidity environment) |

| Sealing level | IP65 (standard type), IP67 (high dustproof requirement type) |

| Applicable fly ash fineness/td> | 80-400 mesh (I-level fine ash 80-200 mesh, II-level medium ash 200-300 mesh, III-level coarse ash 300-400 mesh) |

What is Bucket Elevator for Fly Ash?

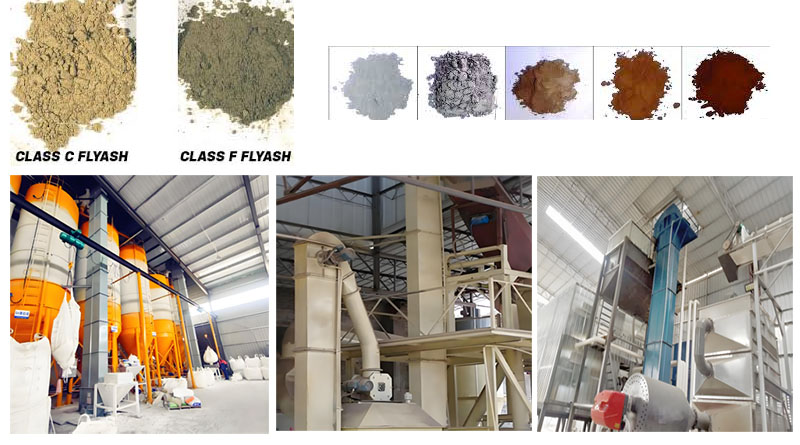

Bucket Elevator for Fly Ash is an elevator used for vertical transportation of powdered materials (such as fly ash, mineral powder, cement, etc.). In view of the characteristics of fly ash, such as dust, moisture absorption, and poor fluidity, we use a fully sealed structure and dust removal system to ensure that there is no leakage during transportation, the dust leakage rate is less than 0.1%, the transportation height is 3-60 meters, and the hourly transportation volume is up to 800 tons. It can effectively realize the recovery and reuse of fly ash, and is used in raw ash lifting, tank silos, ball mill feeding and comprehensive utilization production lines.

Bucket Elevator for Fly Ash can handle Class I, Class II and Class III fly ash, and adapt to working conditions with different fineness (80 mesh-400 mesh) and humidity (≤5%). Its hopper adopts a dense layout and can be selected in various forms such as Q, h, zD, etc., which can meet the transportation needs of different types of fly ash.

What types of Bucket Elevator for Fly Ash are there?

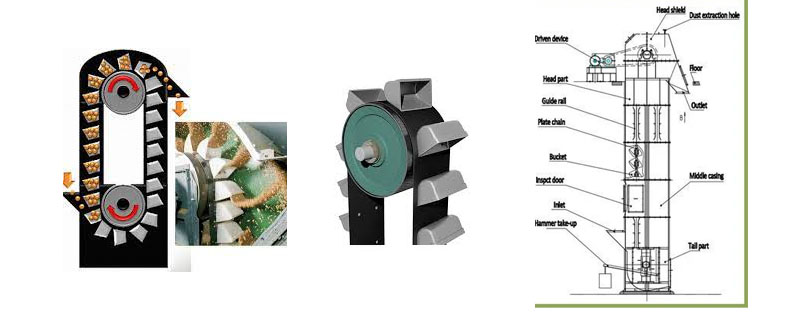

Aiming at the different physical properties and process requirements of fly ash, we provide three types of Bucket Elevator for Fly Ash: chain, plate chain and belt type. Each model is specially designed to adapt to specific fly ash conveying scenarios.

| Model | Conveying capacity | Maximum lifting height | Applicable fly ash type | Power range (kW) | Sealing level |

|

Chain-type Bucket Elevator for Fly Ash

|

50-830m³/h | 60 meters | Fine powder, high abrasive fly ash, Class F fine fly ash (particle size <45μm accounts for more than 80%) | 4-18.5 | IP65 |

| Chain-type Bucket Elevator for Fly Ash | 20-340m³/h | 30-50 meters | Medium-sized, slightly wet fly ash, Class C fly ash and wet ash with a moisture content of <8% | 11 | IP54 |

| Belt-type Bucket Elevator for Fly Ash | 40-60 | 40 | Lightweight, dry fly ash, ultrafine fly ash (particle size <10μm) and modified fly ash | 7.5-15 | IP55 |

For special working conditions, we also provide customized fly ash elevators in explosion-proof, high temperature resistant (up to 250°C) and stainless steel materials to meet the stringent requirements of the chemical, metallurgical and other industries.

Why choose our Bucket Elevator for Fly Ash?

Bucket Elevator for Fly Ash is the preferred equipment in the field of fly ash transportation. It has strong sealing performance, can completely solve the dust problem, has a large conveying capacity, optimized transmission device, and low energy consumption. The specific advantages are as follows:

Solve the dust problem: The sealing structure + pulse dust removal design can effectively prevent the fly ash dust from flying during transportation, and the dust leakage is <0.1mg/m³.

Efficient transportation: The lifting capacity is 1-830 tons/hour, and the lifting height is 5-60 meters. It can be customized according to the transportation needs of fly ash.

Low energy consumption: Compared with ordinary elevators, we optimize the transmission system and use a combination of variable frequency drive and high-efficiency reducer, which saves 30% energy compared to traditional equipment.

Anti-blocking material: The special hopper design can be used for the transportation of wet powder and sticky fly ash.

How does Bucket Elevator for Fly Ash work?

When Bucket Elevator for Fly Ash is working, fly ash enters the bottom hopper evenly through the sealed feeding port. The hopper runs smoothly on the low-friction guide rail. It adopts centrifugal + gravity composite unloading to ensure that fly ash is completely discharged without residue. It integrates pulse backflush system and sets negative pressure dust suction points at key locations to keep the environment clean.

Bucket Elevator for Fly Ash Parameters

| Model | Conveying capacity (m/h) | Maximum lifting height (m) | Hopper volume (L) | Chain speed (m/s) | Power range (kW) | Applicable fly ash bulk density (t/m) |

| NE15 | 10-15 | 35 | 1.2 | 0.5 | 1.5-4 | 0.6-2.0 |

| NE30 | 18.5-31 | 50 | 3.4 | 0.6 | 4-11 | 0.6-2.0 |

| NE50 | 35-60 | 45 | 7.5 | 0.8 | 4-18.5 | 0.6-2.0 |

| NE100 | 75-110 | 45 | 15 | 0.8 | 5.5-30 | 0.6-2.0 |

| NE150 | 112-165 | 45 | 22 | 0.8 | 5.5-45 | 0.6-2.0 |

| NE200 | 170-220 | 40 | 30 | 0.8 | 7.5-55 | 0.6-1.8 |

| NE300 | 230-340 | 40 | 45 | 0.8 | 11-75 | 0.6-1.8 |

| NE400 | 340-450 | 30 | 60 | 0.8 | 18.5-90 | 0.6-1.8 |

| NE500 | 450-550 | 30 | 75 | 0.8 | 30-110 | 0.6-1.8 |

Note: For ultra-light fly ash with a bulk density less than 0.6t/m³, it is recommended to use a larger model and reduce the operating speed to 0.6m/s.

What are the applications of Bucket Elevator for Fly Ash?

Fly ash bucket elevator is suitable for conveying various types of fly ash, whether it is coarse-grained fly ash with hard texture and high abrasiveness after high-temperature calcination, ordinary powdered fly ash with good fluidity, or special fly ash with light weight and high viscosity, it can be efficiently conveyed. It is widely used in the power industry for collecting and transporting fly ash in thermal power plants; the building materials industry helps fly ash enter the production line; the environmental protection industry realizes centralized treatment of fly ash in landfills to meet the needs of different scenarios.

Characteristics of fly ash in different industries and suggestions for selection of hoist

| Application industry | Fly ash characteristics | Recommended model | Key configuration | Typical conveying capacity |

| Thermal power generation | Dry ash, uniform fineness | NE200 | Explosion-proof, high temperature resistant | 150-220m³/h |

| Cement building materials | May contain moisture, strong abrasiveness | TH315 | Wear-resistant sprocket, self-cleaning hopper | 30-50m³/h |

| Commercial fly ash | Ultrafine, low density | TD315 | Low-speed operation, air flow balance | 40-60m³/h |

| Chemical utilization | High temperature, corrosive | NE150 stainless steel version | Corrosion-resistant material, variable frequency drive | 112-165m³/h |

| Environmentally friendly material | Modification treatment, uneven particle size | NE100 | Intelligent adjustment, wide hopper | 75-110m³/h |

Bucket Elevator for Fly Ash Customer Cases

| Application scenarios | Lifting height | Lifting amount | Motor power | Equipment model/features | Special configuration |

| Dust removal ash lifting system for a coal-fired power plant in Southeast Asia | 25m | 60m³/h | 15kW | NE50 plate chain bucket elevator, wear-resistant alloy hopper | Explosion-proof motor configuration |

| Indian fly ash storage tank filling system | 35m | 120m³/h | 30kW | TH315 chain bucket elevator, fully sealed structure | Material level interlocking control |

| US fly ash aerated brick production line | 15m | 40m³/h | 11kW | NE30 plate chain bucket elevator, variable frequency speed regulation | Dust and moisture proof treatment |

| Fly ash grinding system in China | 20m | 80m³/h | 22kW | NE100 plate chain bucket elevator, high temperature resistant design | Temperature monitoring alarm |