Bucket Elevator for Corn

The hopper is continuously operated to lift corn from a low place to a high place, which has the characteristics of high conveying efficiency, small footprint, and low crushing material.

| Lifting height | 3-60 meters (customizable) |

| Conveying capacity | 5~800m³/h |

| Power | 0.75-75KW |

| Dou Kuan | 140-1000mm |

What is Bucket Elevator for Corn?

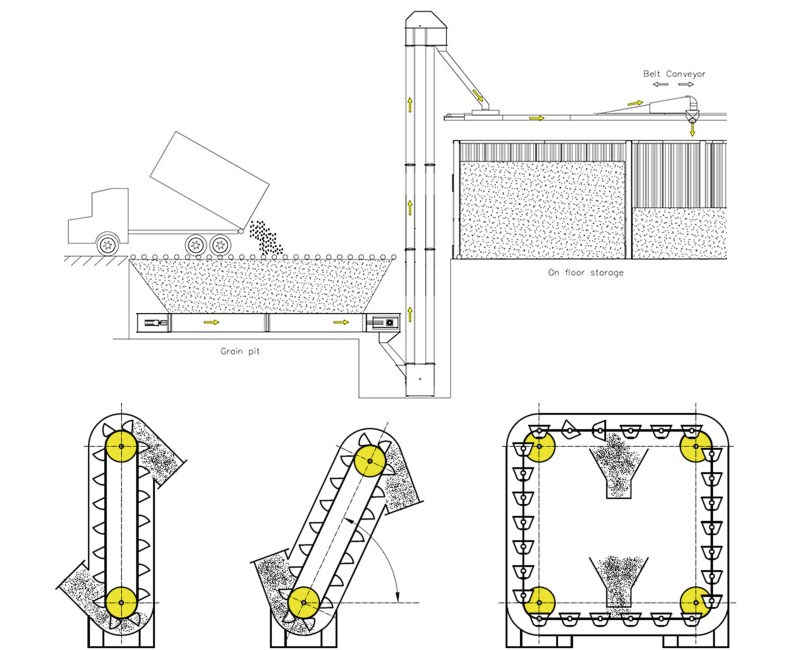

Bucket Elevator for Corn is a device used for vertical conveying of granular materials such as corn. It consists of a drive device, a traction member (belt or chain), a hopper, a casing, etc. Its function is to lift corn from a low place to a high place. The lifting height can reach 5~60 meters. The lifting capacity range is wide, and the small machine is about 5~20 tons/hour, and the large machine can reach more than 500 tons/hour. The hopper can be selected as a deep hopper, a shallow hopper or a sharp-angled hopper: the deep hopper is suitable for dry corn with good fluidity, the shallow hopper is used for materials that are easy to stick, and the sharp-angled hopper is designed for lightweight particles to ensure efficient unloading; the material is available in galvanized steel plate or stainless steel to meet the requirements of different working conditions such as rust resistance and wear resistance, and is widely used in corn storage, processing, threshing and other links.

Why choose Bucket Elevator for Corn?

Corn requires efficient and safe vertical conveying solutions during storage, processing and transportation. Bucket Elevator for Corn is specially optimized for the characteristics of corn grains and has the following irreplaceable advantages over general elevators:

Low crushing rate design: With a special bucket structure and buffer feeding system, the corn crushing rate is less than 0.5%, which is much better than ordinary equipment

Dustproof and sealing performance: The fully enclosed structure effectively prevents corn dust from overflowing, meeting food safety production standards

Wear-resistant and durable: The contact parts are made of wear-resistant steel plates or food-grade stainless steel to adapt to long-term transportation wear of corn

Efficient and energy-saving: The drive system is optimized for corn bulk density (0.7-0.8t/m³), reducing energy consumption by 30%

Anti-blocking design: The feeding and unloading structure is optimized according to the fluidity characteristics of corn to prevent blockage

What types of Bucket Elevator for Corn are there?

Bucket Elevator for Corn has belt type, ring chain type and plate chain type. You can choose the appropriate model according to the corn processing capacity, lifting height and process requirements

| Type | Applicable scenarios | Corn processing capacity | Lifting height | Features |

| Belt type (TD type) | Small and medium-sized grain silos, processing plants | 6-60m³/h | ≤40m | Smooth operation, low noise, low cost |

| Ring chain type (TH type) | Large and medium-sized grain storage | 15-185m³/h | ≤50m | Strong wear resistance, suitable for heavy loads |

| Plate chain type (NE type) | High production line, deep warehouse | 15-800m³/h | ≤45m | Ultra-large conveying capacity, high temperature tolerance |

What is the working principle of Bucket Elevator for Corn?

Bucket Elevator for Corn drives the hopper to circulate through a motor-driven traction belt (or chain). When working, corn is loaded into the hopper at the bottom feed port and rises to the top with the traction belt; under the action of centrifugal force or gravity, the corn is thrown out of the hopper and discharged through the discharge port to complete vertical transportation. The empty hopper goes down to the bottom to continue loading, forming a continuous cycle. The whole process is carried out in a closed manner to reduce dust spillage and ensure efficient and stable transportation of corn.

Bucket Elevator for Corn Parameters

| Model | Lifting height (m) | Conveying capacity (m/h) | Material diameter (mm) | Hopper capacity (L) | Power (kW) |

| TH160 | 32 | 8 | 30 | 2 | 3.0 |

| TH200 | 36 | 15 | 30 | 3 | 5.5 |

| TH250 | 36 | 18 | 40 | 4 | 7.5 |

| TH300 | 36 | 27 | 40 | 4.4 | 11 |

| TH350 | 36 | 32 | 40 | 5.2 | 15 |

| TH400 | 36 | 42 | 50 | 6.3 | 18.5 |

| TH450 | 36 | 48 | 50 | 7.5 | 22 |

What are the applications of Bucket Elevator for Corn?

Bucket Elevator for Corn can transport various corn kernels and corn flour such as dry corn, wet corn, and crushed corn kernels, as well as wheat, soybeans, rice and other grains. It is suitable for granaries, feed mills, food processing, alcohol plants, starch plants and other scenarios.

Bucket Elevator for Corn Customer Cases

| Application scenario | Lifting height | Lifting amount | Motor power | Remarks |

| A grain project in Fangchenggang, Europe: grain silo transportation (shallow silo, vertical silo) | 20-30 meters | 50-60 m³/h | 15-30 kW | Matching belt conveyor system for grain storage transformation |

| A feed factory in Southeast Asia: corn lifting for feed processing | 15 meters | 8-10 m³/h | 5.5 kW | Using TD160 belt bucket elevator, carbon steel material |

| A certain industry in China: corn seed selection and transportation | 12 meters | 15-20 t/h | 7.5 kW | Replace the non-damaged elevator to reduce the corn damage rate |

| An environmentally friendly grain depot in Indonesia: vertical feeding and storage of corn | 40 meters | 40 t/h | 15 kW | Use TD315 steel cord belt, high wear-resistant design |