Bucket Elevator for Coffee Beans

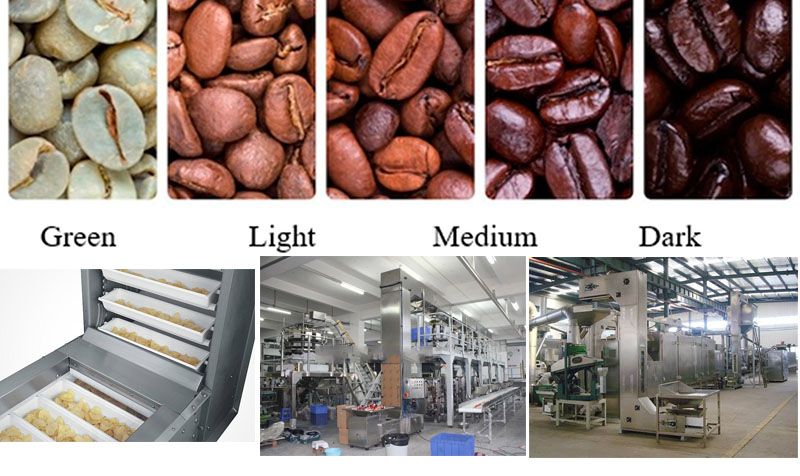

It can be used for vertical lifting of various types of coffee beans, such as green beans and roasted beans, without breaking them

| Lifting height | 5-60 meters (customizable) |

| Transportation capacity | 1-300m³/hour |

| Hopper capacity | 1.8L-10L/hopper |

| Hopper material | 304 stainless steel/food grade PP |

What is Bucket Elevator for Coffee Beans?

Bucket Elevator for Coffee Beans is a bucket elevator used for vertical transportation of coffee beans in the coffee bean processing industry. It lifts the coffee beans vertically or in a Z shape from a low place to a high place through the hopper. The lifting height can reach 60 meters (up to 80 meters for special customization). The conveying capacity ranges from 1 ton/hour4 to 300 cubic meters/hour. It is commonly used in the production links of coffee beans such as cleaning, roasting, and packaging.

Bucket Elevator for Coffee Beans is made of 304 stainless steel or food-grade plastic polypropylene PP. The hoppers include SH-type deep hopper (suitable for dry and loose coffee beans) and ZH-type medium-deep hopper (suitable for coffee beans with higher humidity), which can adapt to coffee beans of different particle sizes and humidity to ensure efficient and hygienic transportation process.

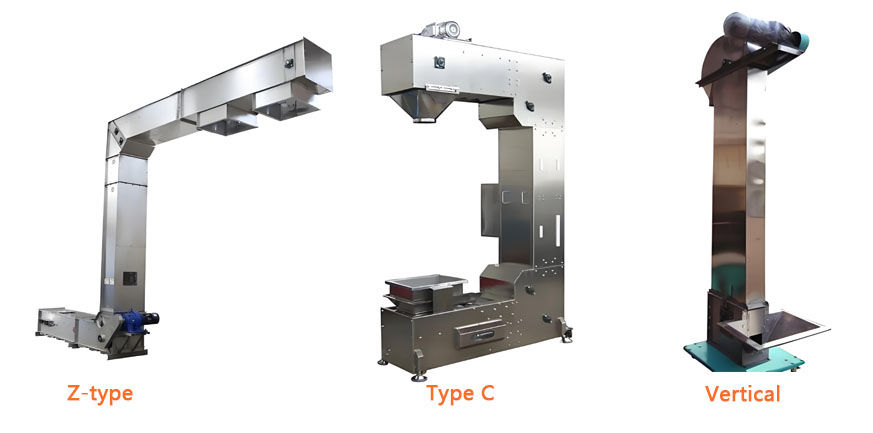

What types of Bucket Elevator for Coffee Beans are there?

Bucket Elevator for Coffee Beans can be divided into three types: Z-type, C-type, and vertical. You can choose the appropriate model according to the characteristics of coffee beans and factory layout requirements:

Vertical Bucket Elevator for Coffee Beans: Traditional high-efficiency design, lifting height up to 60 meters, suitable for centralized transportation of large coffee processing plants

Z-type Bucket Elevator for Coffee Beans: It uses a horizontal-vertical-horizontal path to transport coffee beans, which is suitable for site layout with limited space, and can be fed and discharged at multiple points. It is especially suitable for multi-process coffee processing lines that require sorting and grading.

C-type Bucket Elevator for Coffee Beans: Compact design, small footprint, suitable for small and medium-sized coffee roasting plants, and the conveying path is "C" shaped.

Why choose Bucket Elevator for Coffee Beans?

Bucket Elevator for Coffee Beans is mainly used for vertical transportation of granular coffee beans. It has a fully enclosed design (dust and moisture proof), gentle handling (reduces bean breakage rate), and is adapted to food grade hygiene standards. Its sealed design can effectively isolate external pollution, and there is no dead corner inside, and no material is hidden, ensuring the quality of coffee beans.

Non-destructive conveying technology: Specially designed hoppers and low-speed operation ensure that delicate coffee beans such as Arabica are not damaged during the conveying process and maintain the complete bean shape

Flavor protection system: The closed structure prevents the volatilization of coffee aroma, avoids external pollution, and ensures the pure flavor of coffee.

Versatile adaptability: The same equipment can handle coffee raw materials in different states such as raw beans, roasted beans, and broken beans, and can be adapted by changing the hopper type.

High yield: The conveying capacity of coffee beans can reach up to 100 tons per hour, which saves more than 30% energy compared with traditional conveying equipment

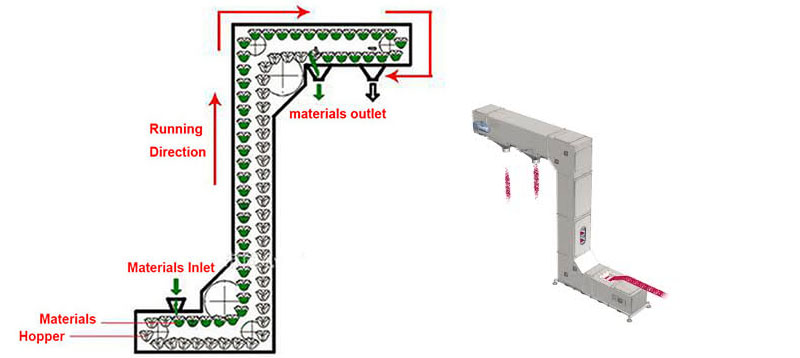

How does Bucket Elevator for Coffee Beans work?

When Bucket Elevator for Coffee Beans is working, coffee beans are evenly put into the bottom hopper through the vibrating feeder. The "scooping" loading method is adopted to avoid impact on the beans. The hopper rises vertically with the chain/belt and runs stably in the closed shell to prevent dust spillage and aroma loss. After reaching the top, the hopper is turned over by "centrifugal" or "gravity" to gently pour the coffee beans into the discharge trough. The specially designed rotating discharge port further reduces the impact force; the empty hopper returns to the bottom along the other side to complete a working cycle.

Bucket Elevator for Coffee Beans Parameters

| bucket volume | 1.8L | 3.6L | 6.5L |

| bucket material | pp | ss304 | ABS |

| body material | mild steel | stainless steel | --- |

| NO.S of discharge port | single | muti-discharge port | --- |

| output | 4-6m3/h | 6.5-8m3/h | 5.5-12m3/h |

| voltage(v) | 220v/240v/as you need | 380v/415v/440v/as you need | as you need |

| speed | adjustable | ||

| conveying capacity | 3-10m3/h | ||

What are the applications of Bucket Elevator for Coffee Beans?

Bucket Elevator for Coffee Beans is suitable for conveying various types of coffee beans, including green beans, roasted beans, crushed beans and coffee powder, and can handle coffee beans of different particle sizes from 0.5-12mm. Its closed structure can effectively reduce dust and breakage to ensure hygiene and safety. The main application scenarios include:

Coffee processing plant (cleaning and roasting of raw beans);

Packaging workshop (filling and lifting of finished beans or powder);

Warehousing logistics (vertical transfer of bulk beans);

Instant coffee production line (continuous conveying of coffee powder)

Bucket Elevator for Coffee Beans Customer Case

| Case name | Equipment used | Lifting height | Conveying volume / processing capacity | Special requirements / project highlights | Operation effect / customer feedback |

| Green bean processing project for a coffee cooperative in China | 2 NE150 stainless steel bucket elevators | 18 meters | 12m³/h | Breakage rate is less than 0.1% | Failure-free operation for 3 consecutive years, processing 50 tons of green beans every day |

| A boutique coffee roasting workshop in Europe | Z-type PP plastic bucket elevator | 6.5 meters | 30m³/hour | Linked control with German PROBAT roasting machine | “Perfectly maintains the integrity of Geisha coffee beans, zero flavor loss” |

| A large Robusta processing plant in Vietnam | 5 ZCT-300 High temperature elevator | 32 meters | 30 tons of shelled coffee beans per hour | High temperature resistant design, suitable for tropical climate environment | 250℃ high temperature transportation, no trouble |