Bucket Elevator for Cocoa Powder

Used to lift cocoa powder (natural powder, alkalized powder, high fat/low fat powder) vertically to a specified height

| Lifting height | 5-30 meters (customizable) |

| Conveying capacity | 1-50 cubic meters/hour |

| Hopper capacity | 1.8L, 4.0L, and 6.0L (Customizable) |

| Hopper material | 304/316L stainless steel/food grade PP |

What is Bucket Elevator for Cocoa Powder?

Bucket Elevator for Cocoa Powder is used for vertical transportation of various cocoa powder raw materials, including cocoa bean fragments, cocoa butter powder, finished cocoa powder, etc. It adopts the "horizontal-vertical-horizontal" Z-shaped path design, which perfectly solves the multi-angle transportation needs of cocoa powder under limited plant space. Compared with traditional vertical elevators, this equipment provides flexible multi-angle transportation solutions, which is particularly suitable for cocoa powder transportation scenarios that need to bypass obstacles or connect production lines on different floors. It can also add or unload materials at a single point or multiple points.

In view of the dust-prone and moisture-absorbent characteristics of cocoa powder, Bucket Elevator for Cocoa Powder adopts a fully enclosed structure, equipped with food-grade conveyor belts and special sealing devices to ensure that the quality of cocoa powder is not affected during transportation. The equipment can be made of carbon steel, 304/316 stainless steel or food-grade PP to meet the hygiene requirements of different grades of cocoa powder.

What types of Bucket Elevator for Cocoa Powder are there?

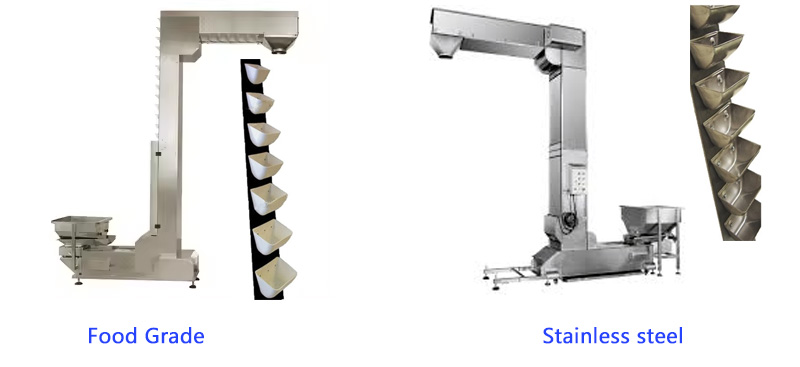

Bucket Elevator for Cocoa Powder can be divided into two types: light food grade and stainless steel. You can choose according to the characteristics of cocoa powder and transportation requirements.

Food grade Bucket Elevator for Cocoa Powder: It uses food grade PU belts and PP hoppers, suitable for gentle transportation of fine cocoa powder and low-fat cocoa powder, with a conveying capacity of 1-10m³/h and a lifting height of 3-15 meters

Stainless steel Bucket Elevator for Cocoa Powder: It uses 304/316L stainless steel, which is wear-resistant and corrosion-resistant. It is suitable for the transportation of granular cocoa powder and cocoa bean fragments, with a conveying capacity of 5-30m³/h and a lifting height of 5-20 meters

Why choose Bucket Elevator for Cocoa Powder?

Cocoa powder (natural powder, alkalized powder, high-fat/low-fat powder) has the characteristics of easy dispersion, easy absorption of moisture and agglomeration, and high hygiene requirements (food grade). Traditional conveying equipment is prone to dust leakage, material damage, and cross contamination - Bucket Elevator for Cocoa Powder can perfectly solve the above problems:

Fully enclosed structure: 304 stainless steel casing + food-grade PP hopper, to prevent dust from spilling when conveying cocoa powder;

Low-speed soft delivery: speed ≤ 0.18m/s, to avoid cocoa powder particle damage (especially for the protection of the crystal structure of alkalized cocoa powder);

Anti-caking design: hopper surface polishing treatment to reduce material residue, optional vibration feeder to prevent material blockage.

Industry lesson: A cocoa factory used ordinary screw conveyors, which increased the risk of dust explosion. After replacing the Z-type elevator, the dust concentration dropped by 90%.

How does Bucket Elevator for Cocoa Powder work?

When the Bucket Elevator for Cocoa Powder is working, the hopper scoops up the cocoa powder at the bottom feed port, and rises vertically along the Z-shaped path along the traction member (chain or belt), turns to the top and then transports horizontally, and then lifts and transports to the designated location for unloading through another vertical section. The motor drives the transmission device to make the hopper circulate, realizing the continuous lifting and transportation of cocoa powder.

Bucket Elevator for Cocoa Powder Parameters

| Model | Conveying capacity (m/h) | Applicable cocoa powder type | Maximum lifting height (m) | Horizontal section length (m) | Power (kW) |

| ZL-5 | 1-5 | Ultrafine cocoa powder | 10 | 8 | 0.75-2.2 |

| ZL-15 | 5-15 | Ordinary cocoa powder | 15 | 10 | 1.5-4 |

| ZM-20 | 10-20 | Containing granulated cocoa powder | 15 | 12 | 2.2-5.5 |

| ZM-30 | 15-30 | Cocoa bean chips | 20 | 15 | 3-7.5 |

| ZH-50 | 30-50 | High capacity delivery | 20 | 15 | 5.5-11 |

What are the applications of Bucket Elevator for Cocoa Powder?

Bucket Elevator for Cocoa Powder can transport different categories such as ordinary cocoa powder, alkalized cocoa powder, high-fat/low-fat cocoa powder, etc. It is suitable for food processing plants (such as raw material lifting of chocolate and cocoa beverage production lines), baking raw material production workshops (material transfer connecting mixing, screening and other processes), cocoa powder storage and logistics links (realizing vertical + horizontal transportation on different floors or areas), and scientific research laboratories (precise transmission of small batches of cocoa powder). Its Z-shaped path is adapted to the layout of multi-story factories, and can complete complex path transportation in a limited space, and the sealed structure can reduce dust spillage.

Bucket Elevator for Cocoa Powder Customer Case

| Case name | Application scenario | Lifting height | Horizontal distance | Conveying volume | Motor power | Equipment model | Special configuration | Customer feedback |

| Renovation project of a chocolate factory in Belgium | Connecting the underground raw material warehouse with the production line on the 3rd floor, bypassing the central air conditioning system | 12 meters | 10 meters (horizontal section) | 18m³/h | 4kW | ZM-20 stainless steel type | Dust-proof design, food-grade PU belt, emergency stop protection device | Save 40% installation space, reduce energy consumption by 35%, and achieve fully enclosed transportation |

| A high-end organic cocoa powder manufacturer in Indonesia | Clean transportation of organic cocoa powder from the purification workshop to the packaging area | 8 meters | 6 meters (horizontal section) | 5m³/h | 2.2kW | ZL-10 sanitary grade | 316 stainless steel, CIP cleaning system, nitrogen protection device | Product contamination rate reduced to below 0.01%, cleaning time shortened by 60% |

| A large food ingredient group in China | Distribution and transportation of cocoa powder mixture between 5 production lines at different heights | 15 meters | 12 meters×2 (double horizontal section) | 45m³/h | 11kW | ZH-50 heavy duty | Explosion-proof motor, online weighing system, intelligent distribution device | Replace 3 traditional equipment, conveying accuracy ±0.5%, annual electricity bill savings of 280,000 yuan |