Bucket Elevator for Chickpeas

A device for lifting chickpeas vertically from a low place to a specified height, and the height can be customized as needed.

| Price | $450.00 - $6,800.00/Set |

| Lifting height | 5-60 meters |

| Lifting volume | 2-200t/h |

| Hopper material | 304/316L stainless steel, food grade PP |

| Lifting speed | 0.5-2.5m/s |

| Power | 1.5-7.5kW |

What is Bucket Elevator for Chickpeas?

Bucket Elevator for Chickpeas is a bucket elevator designed for vertical conveying of chickpeas during chickpea processing. It is commonly used in chickpea cleaning, sorting, packaging, and further processing. It can lift chickpeas from a low location to a desired height, reaching heights of 5-60 meters and transporting 2-200 tons per hour.

Bucket elevators for chickpeas typically feature hoppers made of food-grade plastic (such as polypropylene) or stainless steel, with capacities ranging from 1.8L to 10L. This ensures minimal breakage and wear during chickpea transportation. In chickpea processing, bucket elevators are primarily used for material transfer from the raw material bin to the cleaning equipment, from the sorting machine to the packaging line, and for loading chickpeas prior to puffing or roasting.

What types of Bucket Elevator for Chickpeas are there?

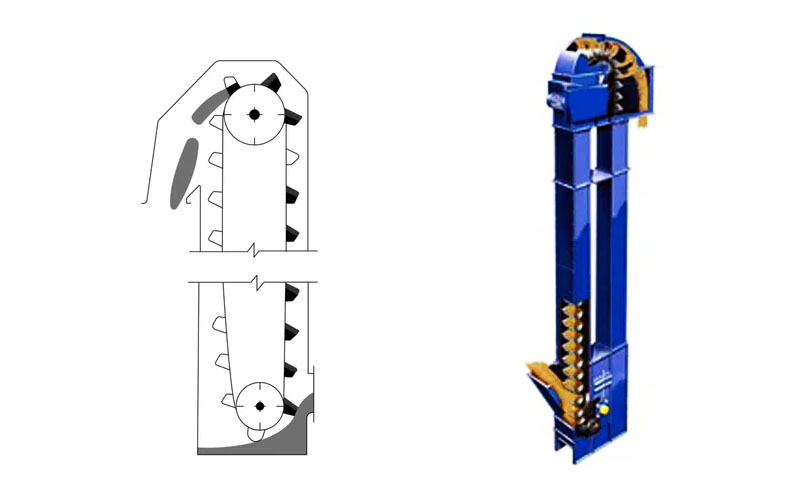

Bucket Elevator for Chickpeas can be divided into three types according to the unloading method: centrifugal unloading, gravity unloading and mixed unloading. The appropriate model can be selected according to the properties of the chickpeas being transported and the application scenario.

Centrifugal unloading: suitable for high-speed lifting of dry chickpeas (1-2m/s), using centrifugal force to eject unloading, equipped with shallow bucket or arc bucket, the processing capacity can reach 15 tons/hour. It is an ideal choice for pre-processing.

Gravity unloading: a low-speed model (0.5-0.8m/s) designed for wet chickpeas after steaming. It adopts a deep bucket close-packed structure and relies on the weight of the material to fall to avoid adhesion. It is particularly suitable for lifting operations in the post-steaming section.

Mixed unloading (Z type/C type): a flexible multi-point conveying system that can run in a horizontal-vertical-horizontal path to realize the conveying of chickpeas between different floors. Z type is suitable for single-point feeding and multi-point unloading, and C type realizes multi-point feeding and single-point collection, providing solutions for complex workshop layouts.

Why choose a bucket elevator for chickpeas?

Bucket Elevator for Chickpeas is a key piece of equipment for chickpea processing and production. It minimizes material breakage during conveying and improves conveying efficiency. Its sealed structure ensures hygiene and safety, adapting to various working conditions and offering high customizability.

Minimize breakage rate: Adopt centrifugal unloading and low-speed operation design (speed can be adjusted to 0.5-1m/s), gently handle each chickpea, keep the beans intact, and control the breakage rate below 0.5%, which is much lower than the 5-8% breakage rate of the screw conveyor.

High efficiency of conveying: 2.2kW motor can achieve a lifting capacity of 10 tons per hour, and the energy consumption is 40% lower than that of the traditional pneumatic conveying system. The inflow feeding design eliminates unnecessary digging resistance and minimizes the ineffective power.

Hygiene and safety: The fully enclosed stainless steel structure eliminates foreign matter contamination, and the food-grade PP hopper ensures that there is no chemical reaction with chickpeas. The lifting pipe adopts bite edge sealing technology to effectively prevent dust leakage and meet FDA and EU hygiene standards.

Intelligent control: It can automatically start and stop through the packaging machine signal, seamlessly connect with the cleaning, sorting, and cooking equipment, realize the automatic control of the whole line, and reduce manual intervention by 30%.

How does Bucket Elevator for Chickpeas work?

After Bucket Elevator for Chickpeas is started, the pre-treated chickpeas are evenly fed into the bottom hopper through a vibrating feeder, and the hopper is pulled vertically up along the closed channel by a food-grade rubber belt or alloy chain. After reaching the top, different unloading methods are adopted according to the machine model - dry beans are accurately fed into the buffer bin by centrifugal ejection; wet beans slide into the cooking equipment along the guide plate by gravity; the empty hopper returns smoothly to the bottom along the inner track to prepare for the next round of loading. The whole process is completed in a sealed environment to isolate the risk of contamination.

What are the applications of Bucket Elevator for Chickpeas?

Bucket Elevator for Chickpeas runs through the entire food processing process: in the raw material processing section, the washed and sorted chickpeas are lifted to the temporary storage bin; in the cooking stage, the wet beans are transported to the cooling tower after cooking; in the packaging section, the finished beans are accurately fed to the weighing and packaging machine. It is also used for material transition between areas with different cleanliness levels, and cooperates with screening, color sorting and other equipment to build an automated production line.

Bucket Elevator for Chickpeas Customer Case

| Customer name | Application scenario | Solution | Achievements |

| A chickpea canning factory in the Mediterranean | Vertical conveying of beans after cooking | Gravity unloading + 316 stainless steel bucket | Annual production capacity increased by 25%, maintenance costs reduced by 40% |

| A healthy snack group | Multi-layer workshop conveying of baked beans | Z-type mixing elevator + anti-static hopper | Energy consumption reduced by 35%, space utilization increased by 50% |

| A production base in the Middle East | Raw material lifting in high temperature environment | Heat-resistant chain structure + forced air cooling system | Continuous operation in 45℃ environment, failure rate reduced by 90% |

| A plant protein company in Asia | Multi-variety line conveying | Dual-channel C-type elevator + food-grade PP hopper | Cross contamination is zero, switching efficiency increased by 3 times |

| An organic bean processing plant in Australia | Organic certified production line | Fully sealed non-lubricated design + no dead angle structure | BioCert certified, market share increased by 20% |

How to select Bucket Elevator for Chickpeas?

Material property analysis

Physical Condition: For dry beans, choose centrifugal discharge with a shallow hopper; for wet/cooked beans, choose gravity discharge with a deep hopper.

Bulk density: <0.8g/cm³: Use a standard model; >0.8g/cm³: A reinforced traction system is required.

Temperature/Humidity: For high-temperature beans (>60°C), choose a chain type; for high-humidity beans, add a non-stick coating.

Production space assessment

Conveying capacity and height: select the model based on 1.2 times of the peak capacity (e.g. 8T/h is required, select 10T/h model); vertical height from feed port to discharge port + 2m margin

Layout: For limited space, select a Z-type or C-type layout; for sufficient linear space, select a vertical layout.

Core configuration selection

Traction Components: Belt-type (quiet and energy-saving) for conventional use; Chain-type (high-temperature resistant) for cooking applications.

Drive Solution and Safety Protection: Direct-drive reducer for <15 meters; Dual-drive anti-skid system for >15 meters; Dedicated motor for high altitudes (>1000 meters); IP65 rating for explosion-proof areas.