Bucket Elevator for Canola

Bucket elevator for vertical conveying of rapeseed

| Elevation height | 2-60m |

| Conveyment capacity | 0.5-686m³/h |

| Power | 3-55KW |

| Hopper volume | 1.8-12.5L |

| Material | Carbon steel/stainless steel |

What is Bucket Elevator for Canola?

Bucket Elevator for Canola is a bucket elevator specially used for vertical transportation of rapeseed. It is optimized for the characteristics of rapeseed such as small particles, easy to break, and high oil content. It adopts a closed structure, which can realize the efficient and lossless lifting of rapeseed from the raw material warehouse to the pretreatment, pressing, and packaging from the low place to the required height, avoiding pollution and loss caused by manual handling.

Lifting capacity: Depending on the model, the conveying capacity is 0.5-686m³/h, which meets the needs of family workshops to 10,000-ton oil plants.

Lifting height: The standard model of Bucket Elevator for Canola can reach up to 60 meters, and the steel core belt model can reach up to 100 meters, which can easily adapt to multi-story factories.

Applicable types: Winter rapeseed (smaller particles), spring rapeseed (full particles), and hybrid varieties are all applicable, and the crushing rate is controlled at <0.5%.

What are the categories of Bucket Elevator for Canola?

According to the traction method and structural differences, Bucket Elevator for Canola is divided into belt type, chain type, steel core belt type, single bucket slope type and other types. You can choose according to the characteristics of the rapeseed being transported and the application scenario:

| Type | Applicable rapeseed type | Lifting height | Transportation volume | Core advantages |

| TD tape bucket elevator for canola | Ordinary rapeseed, low moisture grains | ≤40m | 5.4-142m³/h | Quiet operation, high cost performance |

| TH chain type Bucket Elevator for Canola | High moisture grains, impurities | ≤50m | Up to 365m³/h | High temperature resistance of 250℃, strong impact resistance |

| TG steel core belt type Bucket Elevator for Canola | Continuous operation in large oil mills | ≤100m | 32-686m³/h | Extended life (30,000 hours without failure) |

| Single bucket slope type Bucket Elevator for Canola | Small batch, intermittent operation | ≤12m | 0.3-2t/h | Flexible movement, easy cleaning |

Why choose Bucket Elevator for Canola?

The rapeseed bucket elevator can transport rapeseed without loss. It is made of food-grade 304 stainless steel and has a smooth inner wall design, which effectively avoids oil adsorption and seed damage, and cooperates with low-speed unloading (1-1.8m/s) to prevent spillage; it supports 0.5-50t/h variable frequency adjustment of the conveying volume, accurately matches the feeding rhythm of the oil press, and can realize automatic start and stop through the signal linkage of the packaging machine to reduce energy consumption. In terms of durability, the carburized and quenched chain has a wear resistance that is increased by 3 times, and the service life exceeds 20,000 hours. The sealed casing design meets the grain and oil safety production standards, effectively prevents the risk of dust explosion, and fully guarantees efficient and stable production operations.

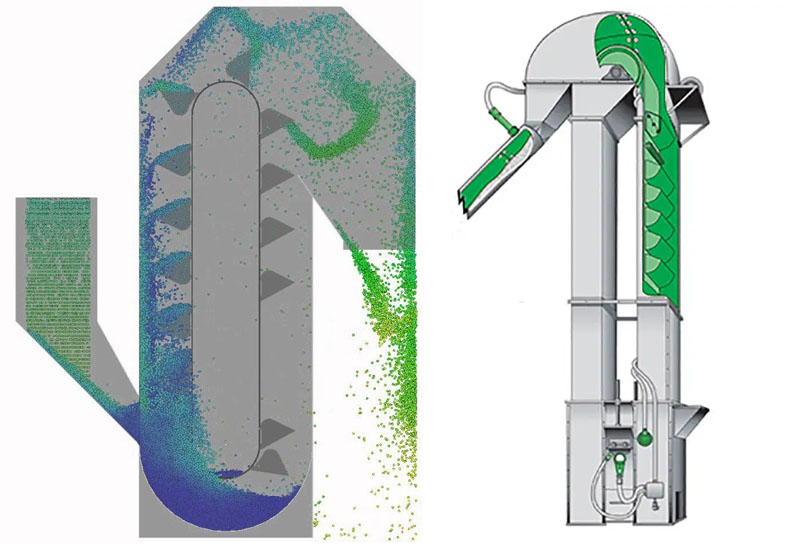

What is the working principle of Bucket Elevator for Canola?

After the Bucket Elevator for Canola is started, the rapeseed flows evenly into the bottom hopper through the vibrating feeder, and the hopper is driven to rise vertically to the designated position through the traction mechanism (belt/chain), and the material is discharged under the dual action of centrifugal force + gravity at the top, and the grains fall into the wok or press intact along the guide groove, with a residual rate of <0.1%.

Bucket Elevator for Canola parameters

What are the applications of Bucket Elevator for Canola?

Bucket Elevator for Canola has a wide range of applications, including: rapeseed pretreatment workshop (lifting raw materials to cleaning screens, stone removers and other equipment), oil mills (connecting woks and presses to achieve automatic feeding), grain and oil storage (for vertical transportation of silo in and out), feed processing (transporting rapeseed meal to the mixing system), biodiesel production (processing industrial rapeseed raw materials), seed processing (non-destructive lifting of high-quality rapeseed seeds) and organic food factories (special conveying systems that meet organic certification requirements), meeting the refined transportation needs of different industries.

Bucket Elevator for Canola Application Case

A small oil mill in Southeast Asia: A single bucket slope elevator (0.5m³ hopper) was used to lift rapeseed from the warehouse to the wok (8m in height), with a daily processing capacity of 20 tons and a 70% reduction in labor costs.

A medium-sized refinery in China: The rapeseed oil company is equipped with a TD250 belt elevator, a dual-channel lifting line, a conveying capacity of 35m³/h, and 24-hour continuous filling.

How to choose Bucket Elevator for Canola?

Determine the type:

Rapeseed with moisture content >10% → Choose TH chain type (rust-proof chain)

Export-grade refined oil plant → Choose all-stainless steel TG model (FDA-compliant)

Calculate parameters:

Lifting capacity = daily processing capacity ÷ operation time × 1.2 (safety factor)

For example: 100 tons of rapeseed are processed daily (10 hours of operation) → Minimum conveying capacity must be ≥10t/h → Choose TD315 type

Select configuration:

High-temperature frying workshop → Install 120℃ resistant food-grade tape

High humidity environment → Configure explosion-proof motor + automatic drain valve