Bucket Elevator for Barley

High-efficiency, low-crushing vertical transportation of various types of barley from low to high

| Lifting height | 3-60 meters (customizable) |

| Transportation capacity | 8~100m³/h |

| Power | 0.75-22KW |

| Capacity | 3L-8L |

What is Bucket Elevator for Barley?

Bucket Elevator for Barley is a device used for vertical transportation of barley such as beer barley and feed barley with a particle size of 2~8mm. It is mainly used to lift barley from a low position (such as raw material bin, discharge port) to a high position (such as drying tower, storage bin or processing equipment) with high efficiency and low crushing. Its lifting height is 3-60 meters, and the conveying capacity range is 8~100m³/h. Different models can be selected according to production requirements. The hopper is shallow or deep, and the material is wear-resistant plastic or galvanized steel plate to ensure smooth loading and unloading of barley.

Barley grains have the characteristics of medium hardness and smooth surface but easy to generate dust. Bucket Elevator for Barley adopts a low-impact design to ensure that the barley remains intact during transportation, with a crushing rate of less than 0.5%. The fully enclosed structure effectively controls dust spillage, and the working environment is cleaner, which meets the hygiene standards of modern food production.

Why choose Bucket Elevator for Barley to lift barley?

Bucket Elevator for Barley is a vertical conveying equipment optimized for the physical properties of barley. It ensures the integrity and quality of barley during transportation through advanced traction system and special hopper design. Its low crushing rate design (less than 0.5%) is far better than the industry standard. The equipment adopts a fully enclosed dust prevention system, and sealing devices are set between each section and at the inspection door to prevent dust leakage. It can also be equipped with a negative pressure dust removal interface to achieve clean and environmentally friendly production. At the same time, it has an efficient conveying capacity of 8m³/h to 100m³/h to meet the needs of different scales, and through the inflow feeding and induced unloading design, the energy consumption is reduced by 30% compared with traditional equipment, achieving energy saving and environmental protection.

What are the categories of Bucket Elevator for Barley?

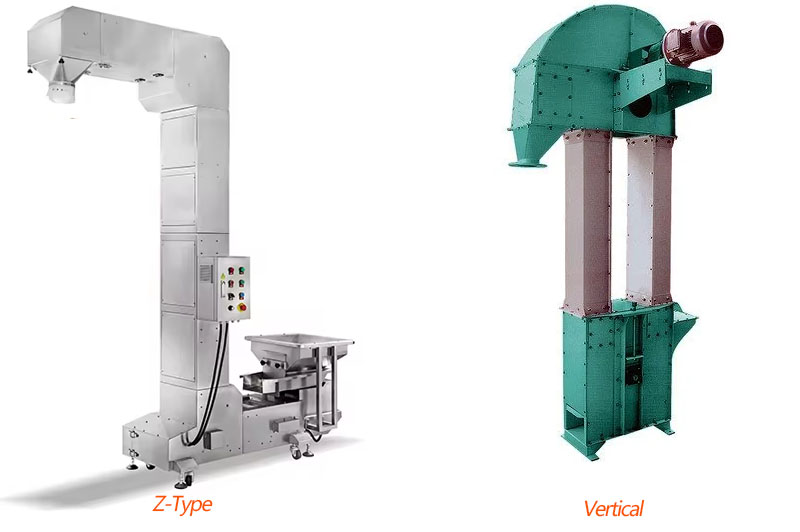

According to the different process requirements and site conditions of barley transportation, we provide a variety of models of Bucket Elevator for Barley, each type has its unique advantages and application scenarios:

Z-type Bucket Elevator for Barley: Designed for plants with limited space, the inlet and outlet are at a 90-degree angle, which can be directly connected to the front and rear process equipment, eliminating the intermediate transfer link. It adopts a fully enclosed dustproof design, which is particularly suitable for the cleanliness requirements of brewery malt workshops and grain processing plants. It can reach a height of 30 meters and a conveying capacity of 50m³/h. It is equipped with a variable frequency speed regulation function and can be flexibly adjusted according to production needs.

Vertical Bucket Elevator for Barley: It uses high-strength alloy steel ring chain as a traction part, which is durable and suitable for large-capacity and high-lifting occasions. The TH315 model has a maximum lifting height of 60 meters and a conveying capacity of up to 100m³/h, which is an ideal choice for large grain storage and processing companies. The sprocket adopts a replaceable rim design, which is easy to maintain and has a service life of more than 50,000 hours.

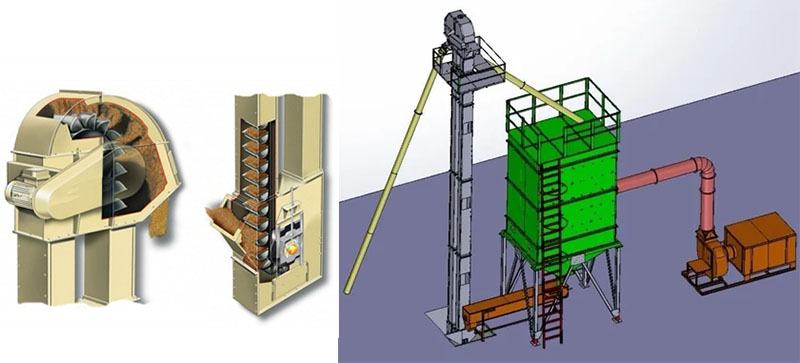

What is the working principle of Bucket Elevator for Barley?

When Bucket Elevator for Barley is working, barley is added from the bottom feed port, and the bucket moving with the chain/belt is loaded at the bottom of the elevator using the "scooping method". The bucket loaded with barley rises vertically with the traction component (chain or belt); when the bucket is lifted to the head discharge port, the barley is discharged from the discharge port under the dual action of gravity and centrifugal force.

Bucket Elevator for Barley Parameters

| Model | Lifting height (m) | Conveying capacity (m/h) | Material diameter (mm) | Hopper capacity (L) | Power (kW) |

| TH160 | 32 | 8 | 30 | 2 | 3.0 |

| TH200 | 36 | 15 | 30 | 3 | 5.5 |

| TH250 | 36 | 18 | 40 | 4 | 7.5 |

| TH300 | 36 | 27 | 40 | 4.4 | 11 |

| TH350 | 36 | 32 | 40 | 5.2 | 15 |

| TH400 | 36 | 42 | 50 | 6.3 | 18.5 |

| TH450 | 36 | 48 | 50 | 7.5 | 22 |

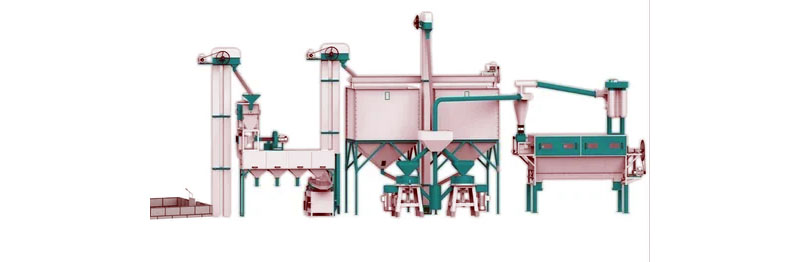

What are the applications of Bucket Elevator for Barley?

Bucket Elevator for Barley can process intact or slightly broken barley grains with a particle size range of 2~8mm, and is suitable for various types of barley, such as beer barley, feed barley, and malt processing barley. The equipment is widely used in breweries, malt processing plants, feed production workshops, grain storage and food processing industries. It can efficiently and low-loss complete the task of transporting barley from the raw material warehouse to the cleaning, grading, drying, storage or processing equipment.

How to choose the right model for Bucket Elevator for Barley?

| Barley type | Recommended elevator type | Features | Typical application |

| Whole barley kernels | TH chain gravity discharge | Low crushing, deep bucket design | Barley storage, primary processing |

| Barley malt | TD belt centrifugal discharge | Smooth conveying, malt protection | Beer brewing process |

| Barley flour | Z-type mixed discharge | Dust-proof, multi-point discharge | Flour mill, food processing |

| High temperature barley | TH ring chain | High temperature resistance 250℃ | Barley conveying after drying |

| Organic barley | Stainless steel hopper type | Easy to clean, no pollution | Organic food production |