Bucket Elevator for Animal Feed

Designed for vertical lifting of various animal feeds such as powdered premixes, pellet feeds and block raw materials

| Lifting height | 3-60 meters, customized according to specific needs. |

| Conveying capacity | 15-400 tons/h |

| Hopper type | Deep bucket (fine powder), shallow bucket (poor fluidity) |

| Drive power | 3-30 kW (adjusted according to height and conveying capacity) |

What is Bucket Elevator for Animal Feed?

Bucket Elevator for Animal Feed is a device that uses the linkage between the bucket belt and the drive device to realize the vertical transportation of various types of animal feed from low to high in a closed casing; it can transport animal feed in powder (such as corn flour, soybean meal), granular (such as compound feed granules), small blocks (such as crushed corn), etc. The lifting height is usually 3-80 meters, and the lifting capacity is generally 5-400 tons per hour, which can meet the needs of feed processing or breeding scenarios of different scales. In terms of material selection, the hopper is mostly made of stainless steel or wear-resistant plastic to resist feed wear and corrosion. The casing is usually made of carbon steel and rust-proof. If special feed is involved, food-grade stainless steel can also be used to ensure the safety and hygiene of the transportation process.

Bucket Elevator for Animal Feed Video

What types of Bucket Elevator for Animal Feed are there?

Bucket Elevator for Animal Feed can be divided into two types: vertical and Z-type, which can follow the animal feed properties and application scenario selection.

| Type | Lifting height | Lifting amount | Applied materials | Typical application scenarios | Advantages |

| Vertical Bucket Elevator for Animal Feed | 3-60 meters | 5-100 tons/hour | Powdered and granular feed with good fluidity (such as corn flour and compound granular feed) | Vertical conveying of raw material warehouse → grinder and finished product warehouse in feed processing plant; vertical feeding of single floor in breeding farm. | Simple structure, easy maintenance, suitable for compact layout. |

| Z-type Bucket Elevator for Animal Feed | 5-30 meters | 6-50 tons/hour | Can handle feed with medium fluidity | Cross-floor feed transportation (such as processing area on the first floor → storage warehouse on the second floor); transportation in workshops that need to bypass equipment. | Flexibly adapt to complex layouts and reduce the space occupied by horizontal conveyor belts. |

Why choose a bucket elevator to lift animal feed?

Compared with general-purpose lifting equipment, the Bucket Elevator for Animal Feed designed specifically for animal feed has the following core advantages:

Wide material adaptability: It can lift various forms of feed such as powder (premix, fish meal), granular (granular feed, expanded feed), small blocks (crushed feed, oil cakes), etc.; the specially designed hopper ensures that the breakage rate of fragile feed (such as shrimp feed, ornamental fish feed) is less than 0.5% during the lifting process.

High efficiency and low energy consumption: The inflow feeding and induced unloading technology are adopted, which reduces the power consumption by 30% compared with the traditional digging type; the large-capacity hopper is densely arranged, and the lifting capacity can reach 100 tons/h, which meets the needs of large feed factories.

Flexible customization service: It provides a variety of material options such as stainless steel, carbon steel spraying, food-grade plastic, etc., and can design a vertical or Z-shaped layout according to the plant space to maximize the use of space.

What is the principle of Bucket Elevator for Animal Feed?

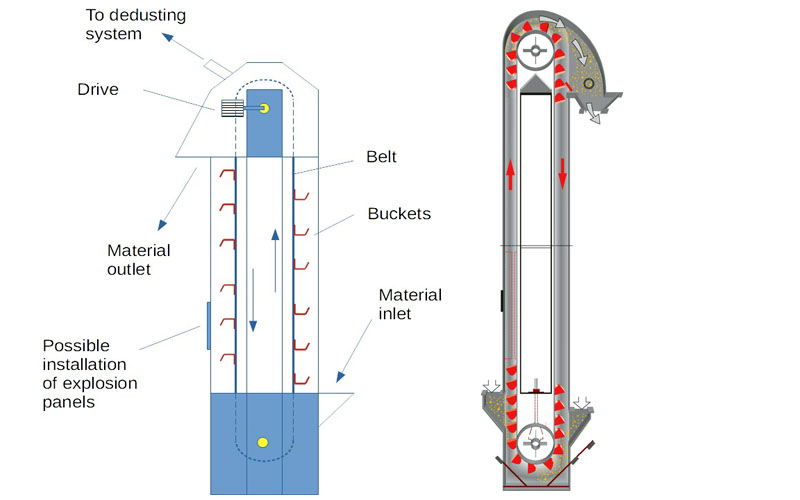

When Bucket Elevator for Animal Feed is working, feed falls from the feed inlet to the bottom, and the hopper moves with the traction belt (or chain) to the bottom to scoop up the feed, and is lifted upward along the closed casing with the traction member. When it reaches the top, the hopper turns with the traction member, and the feed is discharged from the discharge port due to gravity or centrifugal force. The drive device drives the traction member to circulate, and the hopper continuously scoops, lifts, and discharges the feed, realizing continuous vertical conveying of the feed. During the process, the tension of the traction member is maintained by the tensioning device to ensure stable operation.

Bucket Elevator for Animal Feed Parameters

Vertical Bucket Elevator Specifications

| Model | Max feed size(mm) | Capacity(T/H) | Lifting speed(m/s) | Belt width(mm) | Lifting height(m) |

| TD160 | 25 | 5.4-16 | 1.4 | 200 | <40 |

| TD250 | 35 | 12-35 | 1.6 | 300 | |

| TD315 | 45 | 17-40 | 1.6 | 400 | |

| TD400 | 55 | 24-66 | 1.8 | 500 | |

| TD500 | 60 | 38-92 | 1.8 | 600 | |

| TD600 | 70 | 85-142 | 2 | 700 |

Specifications of Z-type bucket elevator

| Model | Conveying capacity (m/h) | Applicable feed type | Horizontal center distance (mm) | Lifting height (mm) | Motor power (kW) |

| ZD106 | 6-8 | Small farm feed | 2000-5000 | 3000-10000 | 1.5-3 |

| ZD205 | 12-15 | Premix for medium-sized feed mills | 2500-6000 | 4000-12000 | 3-5.5 |

| ZD315 | 18-22 | Pellet feed production line | 3000-8000 | 5000-15000 | 4-7.5 |

What are the applications of Bucket Elevator for Animal Feed?

Bucket Elevator for Animal Feed can transport various types of feed, such as powdered feed (such as corn flour, wheat bran powder, soybean meal powder, etc., suitable for poultry feed), pellet feed (such as pig and poultry compound pellets, fish feed pellets, commonly used in large-scale farming), small block feed (such as crushed corn, crushed bean cake, suitable for ruminant feed)/mixed feed (premix containing multiple raw materials) and a small amount of wet feed containing water (pay attention to material preservation); it is often used in feed processing plants for raw material lifting and finished product transportation; it can connect storage silos and feeding equipment in farms; it is used for feed raw material transfer in grain storage scenarios; some integrated breeding workshops are also used for vertical transportation of feed from the processing area to the feeding area to meet the needs of automated and continuous production, especially suitable for large-scale scenarios that require efficient vertical transportation.