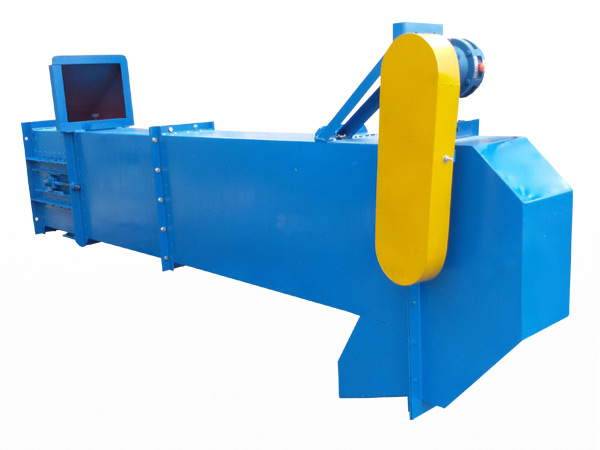

Biomass pellet bucket elevator

Used for continuous transportation of biomass pellets from low to high positions

| Lifting height | 5-60 meters |

| Conveying capacity | 5-100 tons/hour |

| Hopper capacity | 0.5-20L |

| Motor power | 1.5-30kW |

| Applicable materials | biomass pellets, wood pellets, feed pellets, chemical pellets, etc. |

Looking for a reliable bucket elevator for biomass pellet plants? Our custom solutions offer efficient, energy-saving transport with low breakage – the ideal choice for biomass pellet conveying.

What is Biomass pellet bucket elevator?

Biomass pellet bucket elevator is a device used to transport biomass pellets (such as wood chip pellets, straw pellets, feed pellets, etc.). It lifts biomass pellets from a low place to a high place through the cyclic movement of the hopper fixed on the belt or chain. The vertical lifting height can reach 60 meters, and the maximum lifting volume per hour can reach 100 cubic meters. It is widely used in biomass energy, feed processing, agriculture and other fields.

In addition, Biomass pellet bucket elevator can customize the hopper material (such as carbon steel, stainless steel, PP plastic) and drive system according to the characteristics of biomass pellets (humidity, density, particle size) to ensure efficient and stable operation.

What types of Biomass pellet bucket elevators are there?

Biomass pellet bucket elevators can be divided into three types: belt type, plate chain type and chain type according to application scenarios and material characteristics.

Belt-type Biomass pellet bucket elevator: Uses belt as traction member, suitable for conveying small and medium-sized particles.

Biomass pellet bucket elevator with plate chain: Uses chain as traction member, suitable for conveying larger particles or heavier materials.

Chain-type Biomass pellet bucket elevator: Uses chain as traction member, suitable for conveying high-temperature or highly abrasive materials.

Why choose bucket elevator for conveying biomass pellets?

Biomass pellet bucket elevatorIn the biomass pellet production line, material transportation is crucial. Compared with other conveying methods such as belt conveyors and screw conveyors, bucket elevators have irreplaceable advantages in conveying biomass pellets:

Automated transportation: Replace manual handling, improve production efficiency and reduce labor intensity.

Reduce material loss: The inflow feeding and induction unloading methods are adopted to avoid the squeezing and crushing of biomass particles by traditional conveying equipment, thus maintaining the integrity and combustion value of the particles.

Vertical lifting: Able to vertically lift biomass pellets to storage bins, combustion furnaces and other equipment for subsequent processing.

Sealed and environmentally friendly: The fully enclosed structure effectively prevents dust leakage during the transportation of biomass pellets, meeting environmental protection requirements

What are the applications of biomass pellet bucket elevator?

Biomass pellets are solid fuels made from agricultural and forestry waste (such as wood chips, straw, rice husks, etc.) through crushing, drying, compression and other processes. Biomass pellet bucket elevator can be used in the complete biomass pellet production process, such as: raw material pretreatment stage (lifting the crushed wood chips, straw and other raw materials to the dryer), pre-granulation preparation (lifting the dried raw materials to the mixing equipment), finished product transportation (lifting the formed biomass pellets to the cooler or packaging machine), etc. In addition, it can also be used for biomass power plants, biomass heating systems, biomass pellet production lines, biomass energy, feed processing, agriculture, and chemical industry to lift pellet materials.

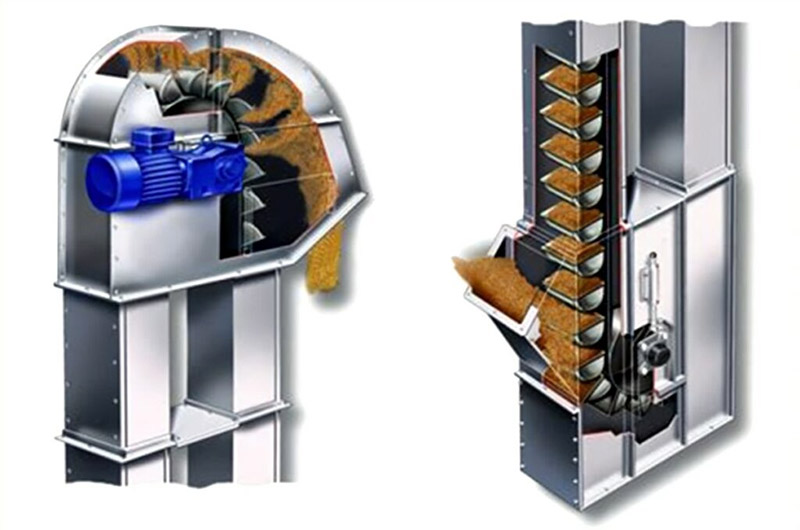

How does the Biomass pellet bucket elevator work?

The bucket elevator uses a motor to drive a belt or chain to drive a hopper fixed on it. After the hopper is loaded with biomass pellets at the bottom, it rises to the top with the belt or chain, and the biomass pellets are unloaded by centrifugal force or gravity, completing the vertical conveying process.

Parameters of Biomass pellet bucket elevator

| Model | Max feed size(mm) | Capacity(T/H) | Lifting speed(m/s) | Belt width(mm) | Lifting height(m) |

| TD160 | 25 | 5.4-16 | 1.4 | 200 | <40 |

| TD250 | 35 | 12-35 | 1.6 | 300 | |

| TD315 | 45 | 17-40 | 1.6 | 400 | |

| TD400 | 55 | 24-66 | 1.8 | 500 | |

| TD500 | 60 | 38-92 | 1.8 | 600 | |

| TD600 | 70 | 85-142 | 2 | 700 |

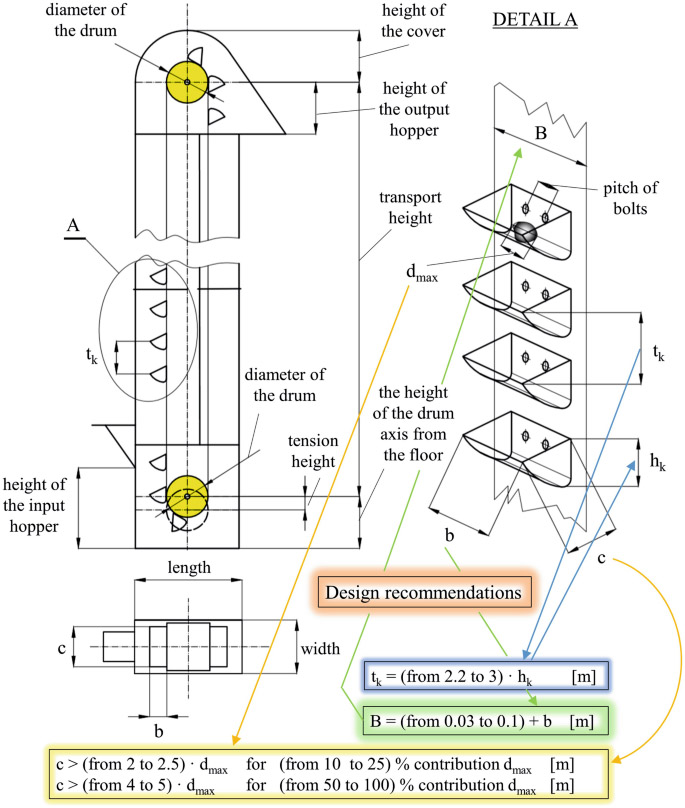

What are the structures of biomass pellet bucket elevator?

Hopper: used to load materials, the material can be plastic, stainless steel or carbon steel.

Belt/chain: used to drive the hopper to move, the chain is suitable for heavy load conditions.

Drive device: includes motor, reducer and drive wheel to provide power.

Casing: closed structure to prevent dust from spilling and material from falling.

Feed port and discharge port: used for material loading and unloading respectively.

Biomass pellet bucket elevator customer case

| Application scenario | Lift height | Lifting capacity | Motor Power | Customer feedback |

| A wood pellet plant in Vietnam with an annual output of 20,000 tons selected our TDTG36/18 biomass pellet bucket elevator to deliver dried wood pellets from the cooler to the finished product warehouse. | 9.6 meters | 6 tons/hour | 3 kW | Smooth and noiseless operation, extremely low particle breakage rate, greatly improving the efficiency of the packaging line. |

| A large biomass energy company in Poland uses our TDTG40/23 bucket elevator to transport pellets pressed from wheat straw, bark, etc. to 4 storage silos. | 12 meters | 10 tons/hour | 4 kW | Multi-point discharge design is adopted, which is compatible with different material particle diameters and meets the needs of multiple categories of warehouse discharge. |

| A customized TDTG50/28 bucket elevator is used in an export-oriented fuel pellet plant in British Columbia, Canada, which is used to vertically transport particles from the underground warehouse to the loading port in the port workshop. | 15 meters | 15 tons/hour | 5.5KW | Fully enclosed structure design, dust and rainproof, adaptable to the complex outdoor environment of the port, and easy equipment maintenance. |

How to choose Biomass pellet bucket elevator?

Material characteristics: particle size (hopper specifications must match particle diameter), density (select special models for low-density materials), fragility (use low-breakage conveying design), humidity: (select stainless steel and other anti-corrosion materials for high moisture content)

Conveying capacity and vertical height: 5-100 tons per hour, lifting height 5-60 meters optional, customized on demand , peak production time must be considered to ensure the maximum load of the elevator.

Hopper material: select plastic/stainless steel/carbon steel according to material characteristics

Drive system selection: belt drive (light load scenario, easy maintenance), chain drive (heavy load or large production requirements)