Bentonite conveying bucket elevator

It is a device used for conveying bentonite vertically or obliquely and can be used in industrial situations where large amounts of bentonite need to be conveyed.

| Lifting height | 10-50 meters, customized according to specific needs. |

| Conveying capacity | 5.4-365 cubic/hour |

| Hopper capacity | 5-10 L |

| Motor power | 5.5-7.5 kW |

| Material temperature | ≤250℃ |

| Material | The hopper and shell are usually made of wear-resistant and corrosion-resistant steel or stainless steel. |

What is a Bentonite conveying bucket elevator?

Bentonite conveying bucket elevator is a mechanical device specially used for vertical conveying of bentonite. It lifts bentonite from a low place to a high place through a series of buckets fixed on chains or belts. It can be used in industrial occasions where continuous and efficient conveying of bentonite is required.

What is the purpose of Bentonite conveying bucket elevator?

Vertical conveying of bentonite: mainly used to convey bentonite from the ground or low place to a high place, such as a storage silo, reactor or mixing equipment.

Continuous production: suitable for industrial processes that require continuous and automated production.

Reduce dust pollution: the closed design can reduce the dust diffusion of bentonite during the conveying process and improve the working environment.

What are the applications of bentonite conveying bucket elevator?

Foundry industry: bentonite is an important binder for foundry sand, and bucket elevators are used to convey bentonite to sand mixing equipment.

Oil and gas industry: bentonite is used for drilling mud, and bucket elevators are used to convey bentonite to mud mixing equipment.

Chemical industry: Bentonite is used as a catalyst or adsorbent, and bucket elevators are used to transport bentonite to reactors or storage silos.

Environmental protection industry: Bentonite is used for wastewater treatment, and bucket elevators are used to transport bentonite to treatment equipment.

Bentonite conveying bucket elevator customer case

| Customer Cases | Application Scenarios | Lifting Capacity | Lifting Height | Equipment Features |

| Foundry Bentonite Transportation | Foundry Sand Treatment (Molding Sand Additives) | 80 m³/h | 25 m | High temperature resistant design (200℃), dustproof seal, reduce bentonite crushing |

| Feed mill bentonite addition system | Animal feed mixing (trace element carrier) | 50 m³/h | 15 m | Food grade stainless steel bucket, pollution-free transportation, equipped with vibrating feeder |

| Mining bentonite powder lifting | Bentonite ore powder processing (packaging after drying) | 120 m³/h | 35 m | High wear-resistant chain + heavy hopper, continuous operation, suitable for high dust environment |

| Chemical Z-type lifting line | Bentonite modified chemicals (horizontal + vertical conveying) | 60 m³/h | 12 m (horizontal span 8 m) | Z-type layout, space saving, variable frequency speed control, explosion-proof motor |

How does the bentonite conveying bucket elevator work?

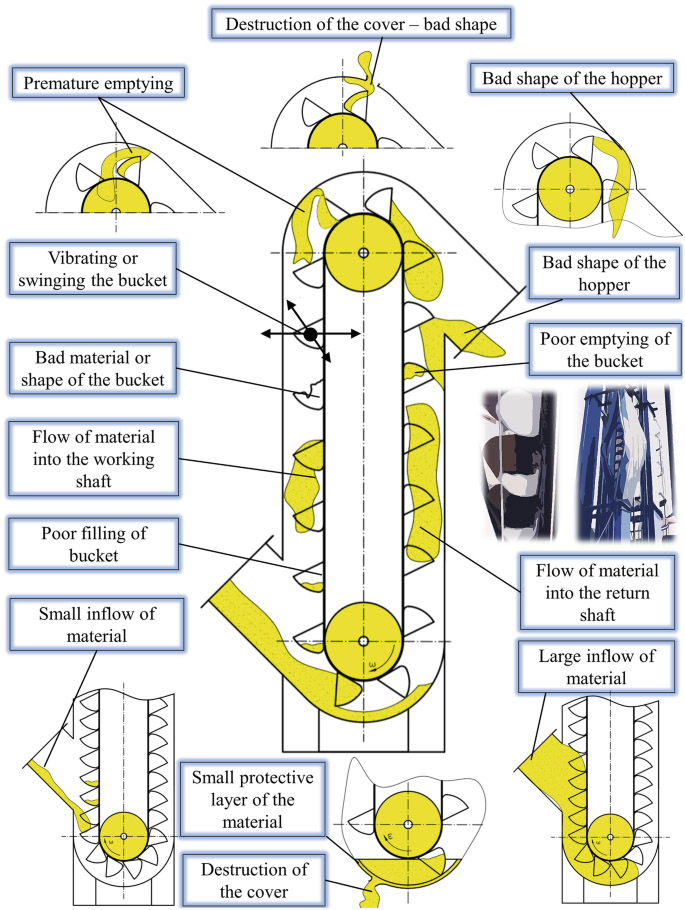

When the Bentonite conveying bucket elevator is working, bentonite enters the bucket elevator from the bottom, and the bucket is loaded with bentonite at the bottom. Through the movement of the chain or belt, the bucket lifts the bentonite vertically to the specified height. At the top, the bucket unloads the bentonite to the discharge port by gravity or centrifugal force. The empty bucket returns to the bottom and is reloaded with bentonite to form a continuous cycle.

Bentonite conveying bucket elevator parameters

| Model | TD160 | TD250 | TD315 | TD400 | ||||||||||||

| Hopper form | Q | h | zD | Sd | Q | h | zD | Sd | Q | h | zD | Sd | Q | h | zD | Sd |

| Delivery volume(m3/h) | 5.4 | 9.6 | 9.6 | 16 | 12 | 22 | 23 | 35 | 17 | 30 | 25 | 40 | 24 | 46 | 41 | 66 |

| Bucket width(mm) | 160 | 250 | 315 | 400 | ||||||||||||

| Dou Rong(L) | 0.5 | 0.9 | 4.2 | 1.9 | 1.3 | 2.2 | 3.0 | 4.6 | 2 | 3.6 | 3.8 | 5.8 | 3.1 | 5.6 | 5.9 | 9.4 |

| Bucket distance(mm) | 280 | 350 | 360 | 450 | 400 | 500 | 480 | 560 | ||||||||

| Bandwidth(mm) | 200 | 300 | 400 | 500 | ||||||||||||

| Bucket speed(m/s) | 1.4 | 1.6 | 1.6 | 1.8 | ||||||||||||

| Bulk material(mm) | 25 | 35 | 45 | 55 | ||||||||||||

| Model | TD500 | TD630 | TD160 | TD250 | TD350 | TD450 | ||||||||||

| Hopper form | Q | h | zD | Sd | h | zD | Sd | Q | S | Q | S | Q | S | Q | S | |

| Delivery volume(m3/h) | 38 | 70 | 58 | 92 | 85 | 89 | 142 | 4.7 | 8 | 18 | 22 | 25 | 42 | 50 | 72 | |

| Bucket width(mm) | 500 | 630 | 160 | 250 | 350 | 450 | ||||||||||

| Dou Rong(L) | 4.8 | 9 | 9.3 | 15 | 14 | 14.6 | 23.5 | 0.65 | 1.1 | 2.6 | 3.2 | 7 | 7.8 | 14.5 | 15 | |

| Bucket distance(mm) | 500 | 625 | 710 | 300 | 400 | 500 | 640 | |||||||||

| Bandwidth(mm) | 600 | 700 | 200 | 300 | 400 | 500 | ||||||||||

| Bucket speed(m/s) | 1.8 | 2 | 1 | 1.25 | 1.25 | 1.25 | ||||||||||

| Bulk material(mm) | 60 | 70 | 25 | 35 | 45 | 55 | ||||||||||

Bentonite conveying bucket elevator structure

Bucket: used for loading and conveying bentonite, usually made of metal, in the shape of a deep bucket or a shallow bucket.

Chain or belt: used to drive the bucket to move, the chain is suitable for heavy loads, and the belt is suitable for light loads.

Drive device: includes motor, reducer and drive wheel to provide power.

Shell: closed structure to prevent dust diffusion and protect the environment.

Feed inlet and discharge port: located at the bottom and top respectively, used for loading and unloading bentonite.

How to choose a Bentonite conveying bucket elevator?

1. Bentonite characteristics

Density: The bulk density of bentonite is usually 0.8~1.2 t/m³ (need to be confirmed by actual measurement), which affects the calculation of the elevator load.

Flowability: Bentonite is easy to absorb moisture and agglomerate, and its flowability is poor. It needs to avoid adhering to the hopper or the inner wall of the barrel.

Particle characteristics: Powder or fine particles (particle size <1mm), dust-proof design is required.

Corrosiveness: Generally not highly corrosive, but if it contains additives (such as bentonite for fertilizers), anti-corrosion materials need to be considered.

2. Determination of key parameters

Lifting height: Up to 60 meters, the appropriate height can be selected according to the application site.

Lifting volume: Determined according to actual needs (such as 50~100 t/h), 10%~20% margin needs to be reserved.

3. Model selection recommendation

Type: NE plate chain bucket elevator or TD belt bucket elevator is preferred.

NE type: suitable for large height and large capacity, wear-resistant chain, strong load-bearing capacity (recommended NE100~NE300 series).

TD type: smooth operation, suitable for light and medium loads, but the belt needs to be moisture-resistant and non-slip (such as covering nylon core belt).

Alternative solution: If the bentonite is very sticky, consider Z-type clamp bucket elevator (low adhesion design).

4. Hopper design

Deep hopper (such as NE series): suitable for powdery and easy-flowing materials, high filling rate.

Shallow hopper (such as TD series): suitable for lightly sticky materials, more thorough unloading.

Spacing: adjusted according to the lifting speed to avoid material spillage (recommended 250~400mm spacing).

Material: 304 stainless steel or carbon steel galvanized (rust-proof), thickness ≥4mm (wear-resistant).

What is the price of bentonite conveying bucket elevator?

The price of a bentonite conveying bucket elevator varies significantly depending on model, material, capacity, and lift height.

1.Price Range Overview

Entry-level models: $900–$3,000 (small capacity, basic carbon steel)

Mid-range models: $3,000–$10,000 (medium capacity, stainless steel or reinforced chains)

High-end models: $10,000–$50,000+ (large capacity, custom designs, explosion-proof)

2. Price Factors & Technical Specifications

TH series (ring chain): $2,800–$10,000

NE series (plate chain): $3,000-$30,000

TDG (wire belt): 5,000–5,000–50,000

TH250 ($4,500–$7,500), NE100 ($12,000–$20,000), TDG400 ($18,000–$30,000).

Material - Carbon steel: $900–$5,000; Stainless steel: $3,000–$15,000+; Food-grade coatings: +20–30% cost

Capacity:- <50 m³/h: $1,000–$5,000

50–150 m³/h: $5,000–$20,000

>150 m³/h: $20,000+

Lift Height-<20 m: $1,000–$8,000

20–40 m: $5,000–$25,000

>40 m: $20,000+

3.Custom Features

Explosion-proof: $5,000–$15,000

Mobile/Modular: $3,000–$10,000

Z-type layout: $2,000–$8,000 Mobile

Gangue bucket elevator

Gangue bucket elevator