Bauxite conveying bucket elevator

Equipment for conveying bauxite vertically or obliquely

| Lifting height | 10-100 meters, customized according to specific needs. |

| Conveying capacity | 10-500t/h |

| Hopper capacity | 0.5-50 L |

| Motor power | 3-7.5 kW |

| Material | carbon steel, stainless steel, etc. |

| Bucket | Q-type (light bucket), H-type (arc bottom bucket), Zd-type (middle deep bucket), and Sd-type (deep bucket) |

What is a Bauxite conveying bucket elevator?

A Bauxite conveying bucket elevator is a device specially designed for vertical conveying of bulk materials such as bauxite (bauxite ore). It lifts materials through a series of buckets fixed on belts or chains, and is often used in mining, metallurgy, chemical industry and other industries.

Why use a Bauxite conveying bucket elevator?

Efficiency: It can convey bauxite quickly and continuously, suitable for large-scale production.

Space saving: Vertical or inclined design, saving ground space, suitable for production environments with limited space.

Reduce dust: The closed design reduces dust release during material transportation and protects the environment.

Durability: Designed for handling abrasive materials, it has a long service life.

What are the applications of Bauxite conveying bucket elevator?

Bauxite mining: Used to lift bauxite from the mine to the ground.

Aluminum smelting: Used to transport bauxite to processing equipment in aluminum smelters.

Building materials: Also used in the cement and ceramic industries.

Metallurgical industry: Used in the smelting process of bauxite.

Chemical industry: Used for chemical treatment of bauxite.

Bauxite conveying bucket elevator customer case

| Application scenarios | Lift Height | Capacity | Advantages |

| Transporting raw bauxite from primary crusher to stockpile | 35 meters | 450 TPH (tons per hour) | Heavy-duty manganese steel buckets for extreme abrasion resistance;Dust-tight enclosure to minimize material loss in windy conditions;Variable-speed drive for controlled feed into processing plant |

| Feeding crushed bauxite into digestion tanks | 25 meters | 300 TPH | Ceramic-lined buckets for corrosion resistance in high-alkali environment; Explosion-proof motor (ATEX certified) for safety in hazardous areas; Automated lubrication system for minimal maintenance |

| Lifting calcined bauxite to silo for cement additive production | 18 meters | 150 TPH | Heat-resistant belt (up to 200°C) for hot material handling;Vibration sensors for real-time monitoring of belt alignment;Low-noise design for urban plant compliance |

A large aluminum smelter: Use bucket elevators to transport bauxite from storage silos to reactors, improving production efficiency.

A mining company: Use bucket elevators in the bauxite mining process to successfully reduce labor costs and transportation time.

A cement plant: Use bucket elevators to transport bauxite to the production line, reducing the cost of manual handling.

How does a Bauxite conveying bucket elevator work?

Bauxite conveying bucket elevator drives the chain or belt through the motor to drive the bucket fixed on the chain or belt. The bucket is loaded with bauxite at the bottom, and the material is lifted to the top with the movement of the chain or belt, and then discharged by gravity or centrifugal force.

Bauxite conveying bucket elevator model parameters

| Model | Max feed size(mm) | Capacity(T/H) | Lifting speed(m/s) | Belt width(mm) | Lifting height(m) |

| TD160 | 25 | 5.4-16 | 1.4 | 200 | <40 |

| TD250 | 35 | 12-35 | 1.6 | 300 | |

| TD315 | 45 | 17-40 | 1.6 | 400 | |

| TD400 | 55 | 24-66 | 1.8 | 500 | |

| TD500 | 60 | 38-92 | 1.8 | 600 | |

| TD600 | 70 | 85-142 | 2 | 700 |

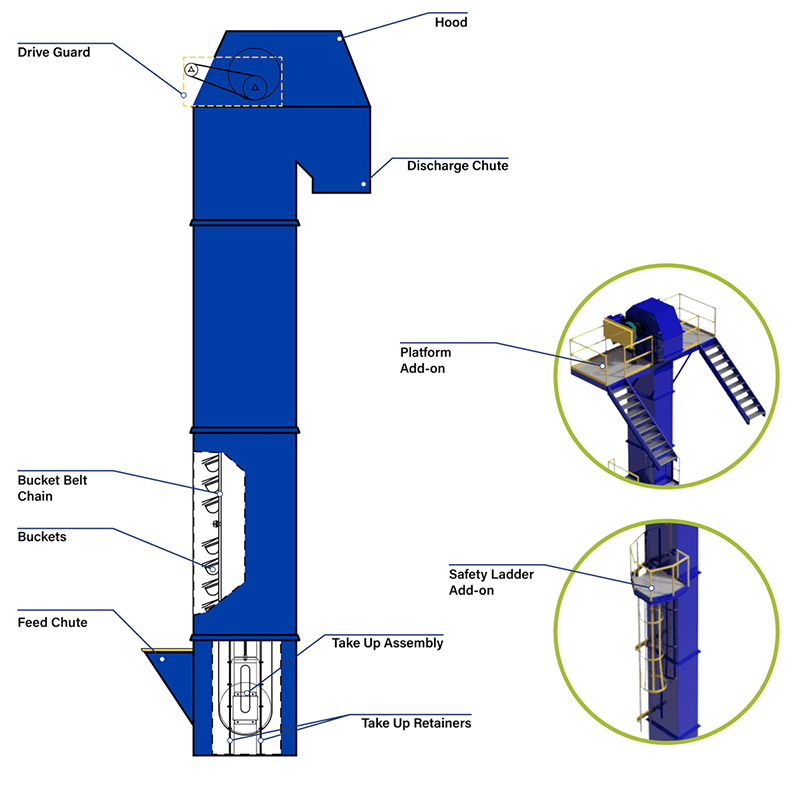

Bauxite conveying bucket elevator structure

1. Lifting bucket: the part used to hold bauxite, usually made of wear-resistant materials.

2. Transmission device: motor, reducer, etc., responsible for driving the operation of the elevator.

3. Frame: support the structure of the entire elevator to ensure the stability of the equipment.

4. Feeding and unloading device: used for the input and output of materials.

How to select a Bauxite conveying bucket elevator?

Material characteristics: understand the particle size, humidity, abrasiveness, etc. of bauxite.

| Factor | Requirement | Recommended Solution |

| Abrasion | High wear resistance | Manganese steel buckets + rubber belts |

| Dust Control | Fully enclosed + dust extraction | Sealed design + filter ports |

| Moisture/Corrosion | Wet/alkali-resistant materials | Stainless steel + non-stick coatings |

| Capacity | 50-500 TPH, 10-60m height | Centrifugal/continuous discharge |

| Temperature | Up to 300°C handling | Heat-resistant belts + cooling systems |

Lifting height and conveying capacity: The maximum height can reach 60 meters and the lifting capacity can reach 100 tons/hour.

Space constraints: consider the installation space of the equipment and choose a suitable design.

Budget: choose equipment with high cost performance according to the budget.

How much does a bucket elevator cost?

Prices vary by model, specification, material, and brand. Generally speaking, the price of a small bucket elevator ranges from a few hundred dollars to tens of thousands of dollars, and the price of a large device may be as high as hundreds of thousands of dollars. The specific price needs to be determined based on customer needs and manufacturer quotations.

Cement clinker conveying bucket elevator

Cement clinker conveying bucket elevator