Aggregate Conveying Bucket Elevator price

Friday October-24 2025 15:29:34

Aggregate conveying bucket elevator prices typically range from $800 to over $50,000. This wide range depends primarily on the model, material, height, lifting capacity, and features. Small-capacity models with a capacity of 5-20 tons/hour may cost between $8,000 and $5,600, while heavy-duty industrial elevators with a capacity of over 100 tons per hour can range from $10,000 to over $50,000. This is because larger equipment requires stronger construction and a more powerful drive to operate stably under high loads.

Aggregate conveying bucket elevator price table (for reference only)

| Model | TH315 | TH400 | TH500 | TH630 | TH800 | TH1000 | ||||||

| Bucket type | Zh | Sh | Zh | Sh | Zh | Sh | Zh | Sh | Zh | Sh | Zh | Sh |

| Delivery capacity (m3/h) | 21 | 36 | 36 | 56 | 45 | 70 | 68 | 110 | 87 | 141 | 141 | 220 |

| Bucket width (mm) | 315 | 400 | 500 | 630 | 800 | 1000 | ||||||

| bucket capacity (L) | 3.75 | 6 | 5.9 | 9.5 | 9.3 | 15 | 14.6 | 23.6 | 23.3 | 37.5 | 37.6 | 58 |

| Bucket distance (mm) | 500 | 600 | 688 | 688 | 920 | 920 | ||||||

| Chain Specifications | Φ18×50 | Φ18×50 | Φ22×86 | Φ22×86 | Φ26×92 | Φ26×92 | ||||||

| Chain pitch diameter (mm) | 630 | 710 | 800 | 900 | 1000 | 1250 | ||||||

| Bucket speed (m/s) | 1.4 | 1.4 | 1.5 | 1.5 | 1.6 | 1.6 | ||||||

| Price (USD) | $800-$8900 | $3500-$13000 | $5700-$23000 | $7500-$35000 | $9800-$42000 | $10500-$50000 | ||||||

What impact do different types have on the Aggregate Conveying Bucket Elevator price?

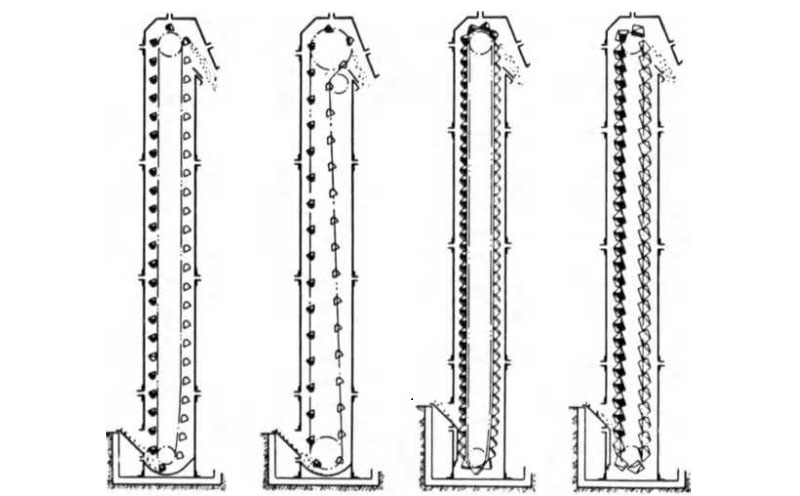

Aggregate Conveying Bucket Elevator price is affected by type. Different types of equipment can convey different materials, lifting heights, and lifting capacities. They are mainly divided into three types: belt type, chain type, and plate chain type. You can choose the appropriate type according to the properties of the conveyed material.

Belt-type aggregate conveying bucket elevators range in price from $800 to $22,000, making them relatively affordable. They primarily use a rubber or steel cord belt as a traction mechanism to drive the hopper and lift aggregates. They are not heat-resistant and should not exceed 120°C. They can be used to lift powdery, granular, lumpy, low-abrasive, or semi-abrasive materials such as coal, sand, cement, and crushed ore. However, they are not suitable for conveying hard, abrasive materials. They can reach a lifting height of up to 40 meters and have a lifting capacity of 15-238 m³/h.

Chain-type aggregate conveying bucket elevators range in price from $2,500 to $32,000. They utilize a round chain as a traction element, boasting high tensile strength. They can transport powdered, granular, and small, highly abrasive materials, as well as wet, sticky materials such as quartz sand, iron ore, coke, gravel, coal, wet sand, and fertilizer. They accept feed sizes up to 150 mm, reach heights up to 50 meters, and have a lifting capacity of 6 to 500 m³/h.

Plate-chain-type aggregate conveying bucket elevators range in price from $4,500 to $50,000. They utilize high-strength alloy steel plate chains to drive the hopper and lift medium-sized, large, abrasive, or high-temperature materials such as limestone, cement clinker, gypsum, and lump coal. Material temperatures can reach 300°C, making them suitable for high-wear, high-load environments. They can reach heights up to 60 meters and have a lifting capacity of 15 to 800 m³/h.

How does material affect the Aggregate Conveying Bucket Elevator price?

Aggregate Conveying Bucket Elevator price is affected by different materials. Different materials have different corrosion resistance, acidity and alkali resistance, and wear resistance. Generally, the price of carbon steel is between US$800 and US$15,000. It is cheaper, but its durability is average and it is easy to rust. It is often used to transport ordinary non-corrosive materials without any hygiene requirements. The price of 304/316L stainless steel with good acid and alkali corrosion resistance is more expensive, about US$3,000 to US$35,000 and above, which is 2-3 times the price of carbon steel. It is often used in humid workplaces with strict hygiene requirements or harsh corrosive environments.

How do height and lifting capacity affect the Aggregate Conveying Bucket Elevator price?

Aggregate conveying bucket elevators vary in price depending on their height and lifting capacity. Generally, the lifting height ranges from 4 to 60 meters. Each additional meter of height requires more consumables and a corresponding price increase of $500 to $1500. Small models with short-distance lifts under 10 meters typically cost between $800 and $78,000. Medium-distance lifts with conveying heights of 10 to 30 meters range from $3,000 to $15,000. High-distance lifts exceeding 30 meters are even more expensive, generally ranging from $5,000 to $30,000 or more. The price also increases depending on the lifting capacity, the model selected, and the drive configuration.

What impact does customization have on the Aggregate Conveying Bucket Elevator price?

In terms of customization, the Aggregate Conveying Bucket Elevator price will also be different. When the standard model cannot meet the needs, relevant configurations need to be customized, including hopper size, motor configuration (ordinary motor replaced with explosion-proof motor or variable frequency motor), cooling jacket, etc. Standard models, which only lift materials, are relatively inexpensive, but can be equipped with additional features such as mobility (universal wheels can be installed at the bottom of the elevator for flexible mobility and to accommodate material lifting in various work locations), dust removal (a dust collector can be included to purify dust generated during operation), and explosion-proof features (for lifting flammable and explosive powder materials or for use in coal mines, such as explosion-proof motors and electronic control systems). Each added feature increases the cost by $500-$5,000. Elevators with mobility are $1,500-5,000 more expensive than standard models, while explosion-proof models can cost several times more, reaching over $10,000.

Aggregate Conveying Bucket Elevator price is also related to the capacity of the hopper, motor power and drive system, etc. The price is not fixed. When selecting an aggregate conveying bucket elevator, consider the aggregate's hardness, particle size, moisture content, viscosity, abrasiveness, and other properties, as well as the required lifting height and lifting capacity, to determine the most cost-effective equipment. Aggregate conveying bucket elevators offer lifting heights ranging from 4 to 60 meters and lifting capacities ranging from 5 to 800 cubic meters per hour. Available hopper capacities include 1L, 1.8L, 2L, 4L, and 6L. Customization is also possible, but this will increase costs.