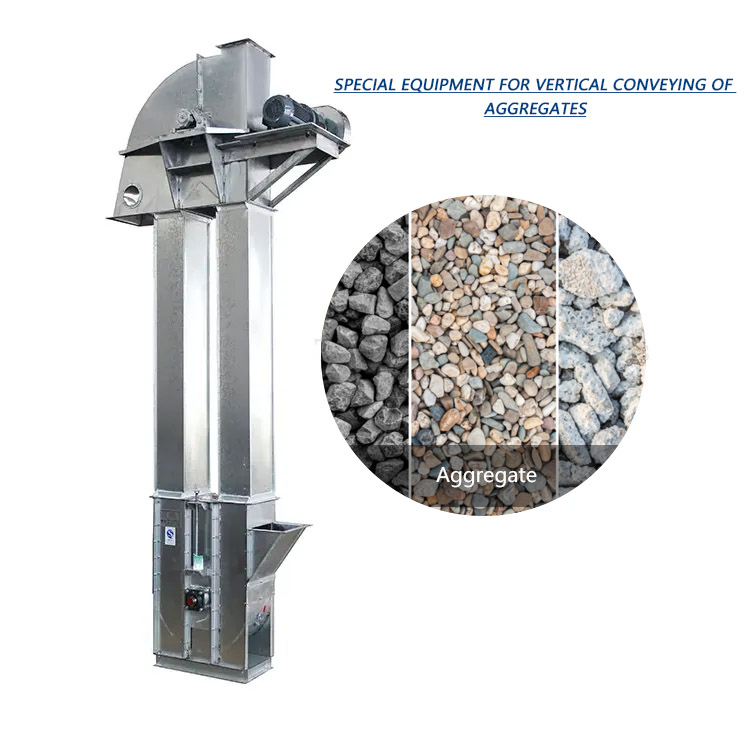

Aggregate Conveying Bucket Elevator

Used to transport bulk materials like aggregates (sand, gravel, crushed stone) efficiently.

| Lifting height | 5-30 m |

| Conveying capacity | 10-100 t/h |

| Hopper capacity | 0.5-5 L |

| Motor power | 2.2-22 kW |

| Operating speed | 1-2 m/s |

What is Aggregate Conveying Bucket Elevator?

Aggregate conveying bucket elevator is a mechanical equipment specially used for vertical conveying of aggregates such as sand, gravel, machine-made sand, slag, etc. It is widely used in industries such as construction, building materials, mining and concrete mixing plants. It lifts aggregates from low to high places through a bucket fixed on a belt or chain, and is suitable for processes such as crushing, screening, storage or loading.

Aggregate Conveying Bucket Elevator Video

What are the applications of Aggregate Conveying Bucket Elevator?

Aggregate Conveying Bucket Elevator is commonly used in aggregate processing. It can be used to transport sand, gravel, concrete, machine-made sand and other construction materials in the construction industry, ore and coal in the mining industry, metallurgical industry to transport metal minerals and alloys, chemical industry to transport chemical raw materials and powders, etc.

| Application scenarios | Typical conveying capacity (t/h) | Common lifting height (m) | Main materials |

| Sand and gravel yard | 50-200 | 15-30 | Q345B wear-resistant steel |

| Concrete station | 20-100 | 10-25 | 304 stainless steel |

| Mine crushing | 100-500 | 20-40 | NM400 wear-resistant plate |

| Cement plant | 30-150 | 20-35 | Heat-resistant steel |

Aggregate Conveying Bucket Elevator Customer Case

| Application Scenario | Lifting Amount | Lifting Height |

| Used for vertical lifting of raw materials such as clinker and limestone in cement production lines to ensure continuous feeding to the pre-homogenization yard or mill feed inlet. | 150 tons/hour | 30 meters |

| Used for lifting grains such as wheat and corn in large granaries, transporting them from the ground to the top of the silo for storage or loading. | 80 tons/hour | 25 meters |

| In the sand and gravel crushing and screening system, it is used to lift crushed stone and machine-made sand to the vibrating screen or finished product pile. | 200 tons/hour | 15 meters |

What are the advantages of Aggregate Conveying Bucket Elevator?

Aggregate Conveying Bucket Elevator can vertically transport aggregates of various sizes, is sealed and dustproof, and has large output. The following are the specific advantages:

Large-capacity vertical conveying: The lifting height of a single machine can reach 60 meters (special design can reach 80 meters), the conveying capacity is 800 tons/hour, and the vertical conveying efficiency is more than 30% higher than that of the inclined belt conveyor.

Conveying a variety of aggregates: It can handle aggregates of various particle sizes from 0 to 50 mm, suitable for crushed stone (Mohs hardness ≤8), machine-made sand, recycled aggregates, etc. The special design can convey wet materials with a moisture content of ≤8%

Space saving: The floor area is only 1/3 of the belt conveyor, and it can be flexibly arranged in a narrow space. Vertical conveying reduces the horizontal conveying link

Durability: It uses high-strength materials to adapt to harsh working environments.

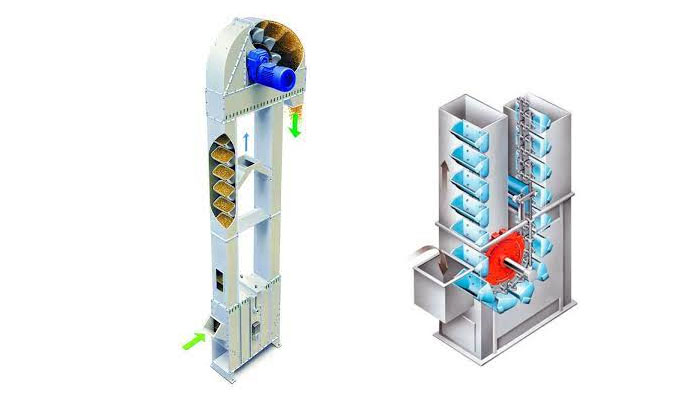

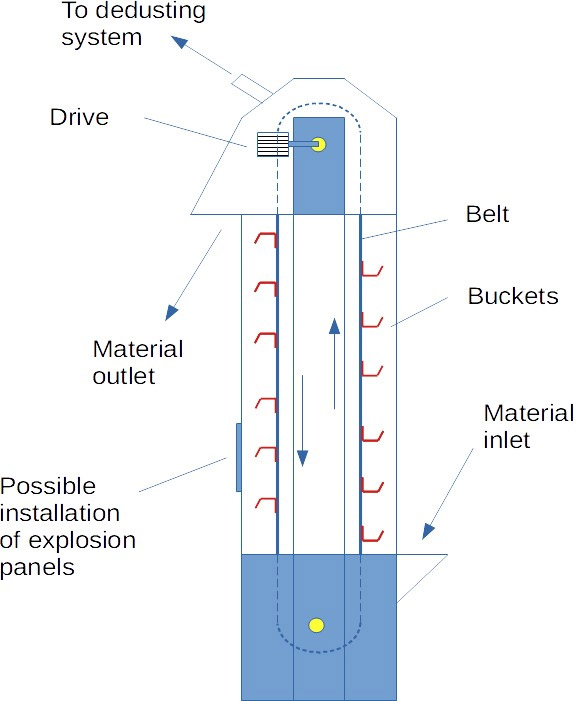

Aggregate Conveying Bucket Elevator Principle

Aggregate Conveying Bucket Elevator drives the lifting belt through the motor, drives the loading bucket to lift the Aggregate from a low place to a high place, and uses gravity and friction to achieve material transportation.

Aggregate Conveying Bucket Elevator Parameters

| Model | Max. Feed Granularity | Capacity | Bucket | Width of Conveyor Belt | |||

| Width | Pitch | Volume | Speed | ||||

| (mm) | (m3/h) | (mm) | (mm) | (L) | (m/s) | (mm) | |

| TD160 | 25 | 5.4-16 | 160 | 280, 350 | 0.5-1.9 | 1.4 | 200 |

| TD250 | 35 | 12-35 | 250 | 360, 450 | 1.3-4.6 | 1.6 | 300 |

| TD315 | 45 | 17-40 | 315 | 400, 500 | 2-5.8 | 1.6 | 400 |

| TD400 | 55 | 24-66 | 400 | 480, 560 | 3.1-9.4 | 1.8 | 500 |

| TD500 | 60 | 38-92 | 500 | 500, 625 | 4.8-15 | 1.8 | 600 |

| TD630 | 70 | 85-142 | 630 | 710 | 14-23.5 | 2 | 700 |

| * More models, support customization, please click here to contact us. | |||||||

What are the structural components of Aggregate Conveying Bucket Elevator?

Aggregate Conveying Bucket Elevator consists of a lifting bucket, a transmission device, a frame, a drive system, etc.

Lifting bucket: used to load and lift materials.

Lifting belt: connects the bucket and the motor to transmit power.

Frame: supports the entire elevator structure.

Drive system: motor and reducer, providing lifting power.

How to select Aggregate Conveying Bucket Elevator?

Analysis of aggregate characteristics

The particle size, humidity, hardness and abrasiveness of aggregate directly affect the equipment selection:

| Parameters | Influence of selection | Solution |

| Particle size | Large aggregate (>50mm) is prone to jamming or impact wear | Use deep bucket/sawtooth bucket, chain drive (impact resistant) |

| Moisture | Wet materials are easy to adhere, resulting in incomplete discharge | Choose a stainless steel hopper or anti-stick coating |

| Hardness | High-hardness aggregates (such as granite) accelerate wear | Use wear-resistant steel hoppers or replaceable liners |

| Clay content | Easy to agglomerate and block the hopper | Enlarge the discharge port and add a vibration cleaning device |

Lifting capacity

Calculation formula of Aggregate Conveying Bucket Elevator: Lifting capacity (t/h) = single bucket volume (L) × bucket distance (m) × lifting speed (m/s) × filling rate (usually 70-90%)

Small output (<50t/h): light belt bucket elevator (such as NE series).

Medium output (50-300t/h): medium chain bucket elevator (such as TH series).

Large output (>300t/h): heavy plate chain bucket elevator (such as TD series).

Lifting height

Below 10m: suitable for short-distance lifting (such as concrete mixing plant).

10-30m: common in sand and gravel aggregate production lines, the structural rigidity needs to be strengthened.

Above 30m: Special design is required (such as dual drive, reinforced chain/belt).

Note: The higher the lifting height, the greater the power requirement, and the tensile strength of the chain/belt needs to be checked.

Bucket Material

| Material | Applicable scenarios | Advantages and disadvantages |

| Carbon steel (Q235) | Dry, low-wear aggregate (such as ordinary sand and gravel) | Low cost, but poor wear resistance |

| Wear-resistant steel (NM360) | High wear aggregate (such as granite, iron ore) | Long life, but high price |

| Stainless steel (304/316) | Wet or corrosive environment (such as sea sand, recycled aggregate) | Rust-proof, but high cost and average wear resistance |

| Rubber-lined | Reduce noise and impact (such as glass aggregate) | Shockproof, but poor high temperature resistance |

Drive System

| Type | Applicable scenarios | Features |

| Belt drive | Small and medium-sized hoists (<50m), light to medium-loaded aggregates | Smooth operation, low noise, but easy to slip |

| Chain drive | Medium and large hoists (>30m), heavy loads or large aggregates | Impact resistant, but requires regular lubrication and maintenance |

| Dual drive | Ultra-high lifting (>50m) or ultra-large capacity (>500t/h) | Even power distribution, reducing the risk of single point failure |

Other key selection factors

Sealing: Aggregates are prone to dust, requiring a fully enclosed housing + dust removal interface (such as a pulse dust collector).

Discharging method: Centrifugal discharging(suitable for small particles and high-speed lifting ,such as sand); Gravity discharging: (suitable for large aggregates (such as crushed stone) and low-speed operation).

Safety device: Anti-reversal device (to prevent aggregate backflow during shutdown), Deviation alarm, overload protection.

Selection flow chart

1. Determine the aggregate characteristics (particle size, humidity, hardness) → 2. Calculate the lifting amount → 3. Select the lifting height → 4. Match the hopper material → 5. Select the power type → 6. Configure sealing/safety devices.

If precise selection is required, specific parameters (such as aggregate density, maximum particle size, working conditions) can be provided to further optimize the solution

Chemical Raw Material Bucket Elevator

Chemical Raw Material Bucket Elevator